If you want to improve he appearance of your bike you can't beat replicating OEM zinc plating. DIY means that l can plate whatever piece l want at a time to suit. Its not particularly difficult or expensive and you can plate to whatever standard you want.

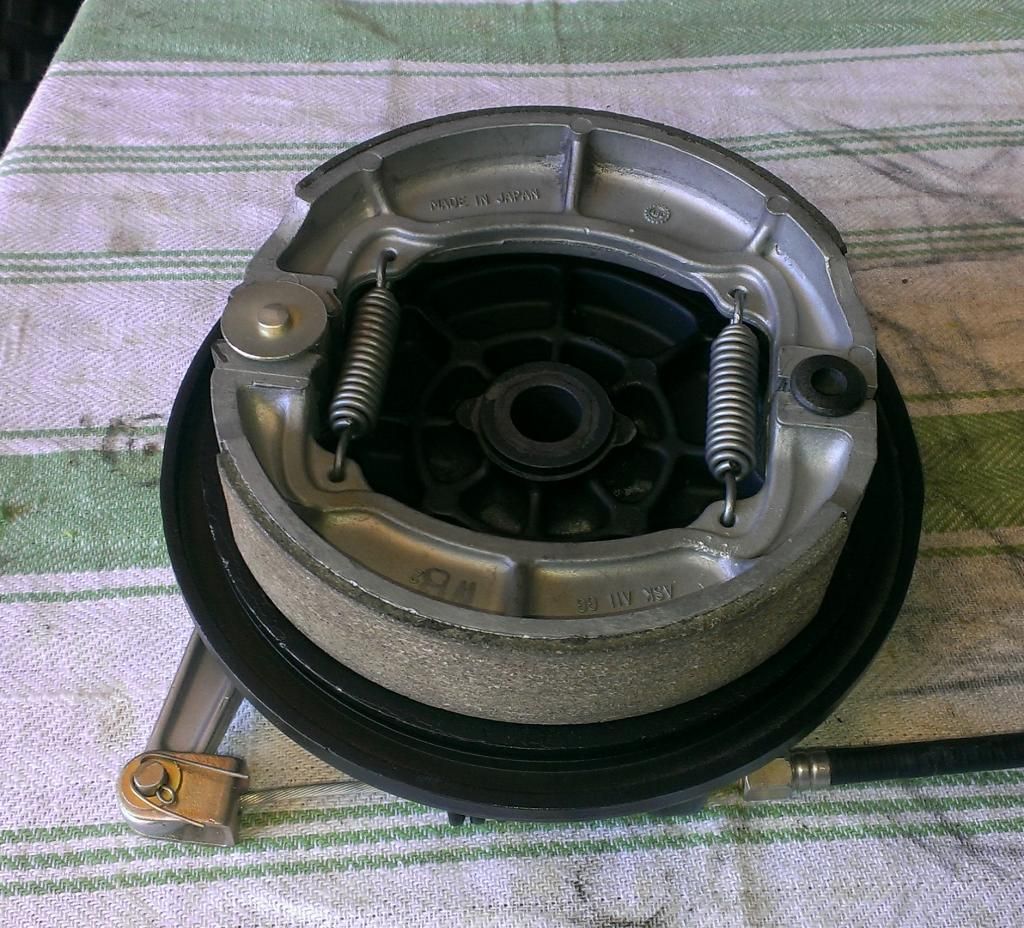

The top cable is the shorter US front brake cable and below is the AU cable. First degrease and bead blast.

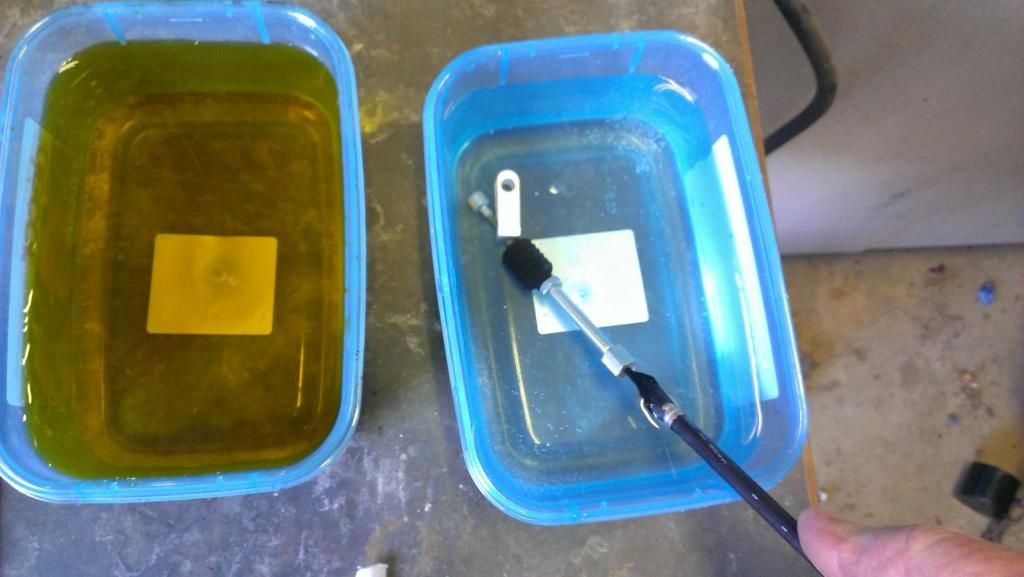

This is a mild solution of pool (hydrochloric) acid. It removes the old zinc platinf but wont move rust or oil/grease so your part must be very clean beforehand.

It doesn't look any different to the above shot but with the zinc removed surface rust can start in a few hours.

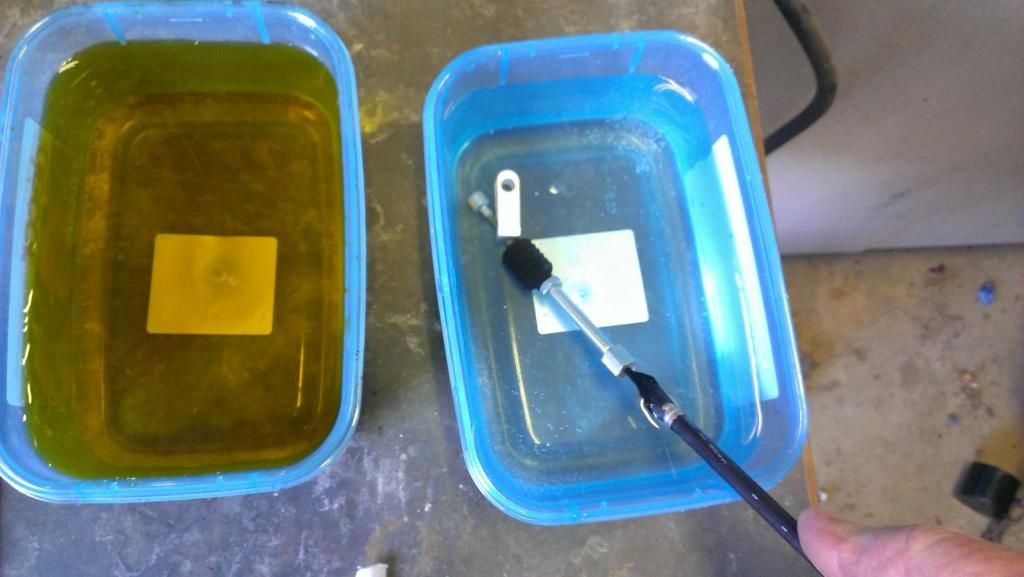

The rubber gloves go on now because the oil in your skin can affect the finish. The parts need to be scrubbed with a detergent super clean and rinsed in distilled water as the chemicals in tap water apparently muck things up.

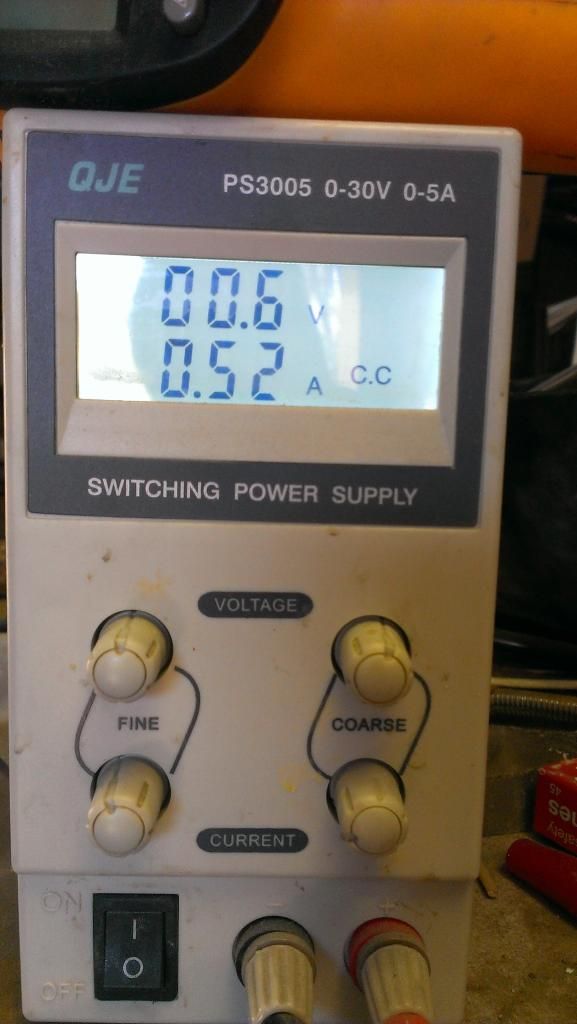

The disc on the right is the zinc anode which gives the zinc coating to the part through the electrolyte (liquid) via an electric current.

l dont go over the top wiring bits up, as long as they're touching it all works well

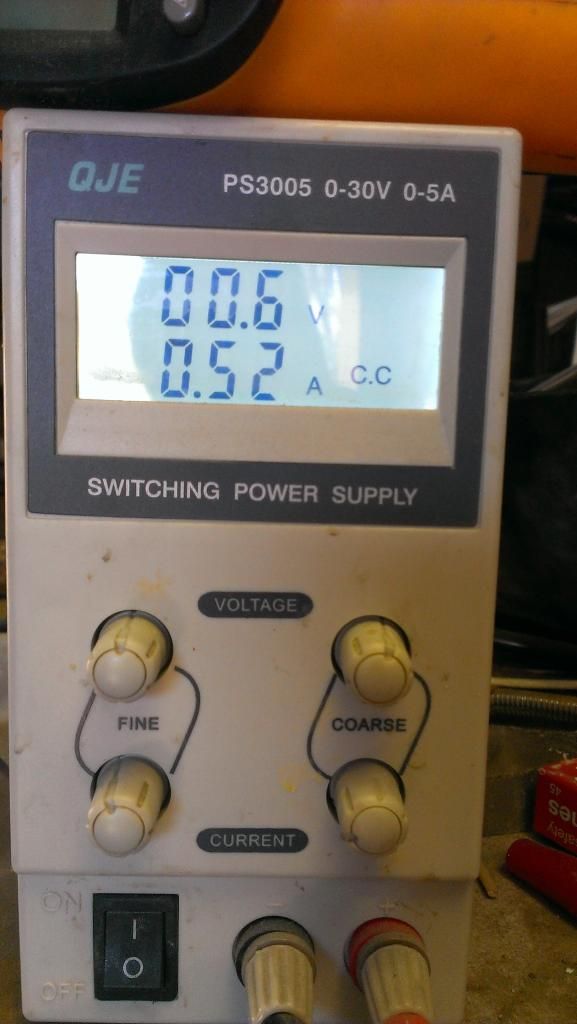

l put half an amp into these parts for around half an hour.

Out comes the part shiny and new

On the right is a pre chromate dip that makes the chromate stick better and make the zinc plating more durable. l dipped the part into the yellow chromate solution for around 10 seconds, longer time equals deeper color.

And here's another one