Page 1 of 1

Smoothing out casting marks on kdx200 head

Posted: 07:30 pm Jan 10 2024

by JZ05220r

I noticed casting marks on the kdx200 combustion chamber. The 220 doesn’t have any casting marks and therefore is perfectly smooth. I’m thinking about having them smoothed. I was wondering if this will be worth doing. I know it will in fact lower the compression ratio slightly but if their any benefit?

Re: Smoothing out casting marks on kdx200 head

Posted: 09:49 pm Jan 10 2024

by SS109

Casting marks in the chamber itself? Weird. Got a pic?

If I could catch my fingernail on it I would smooth it out. Any edge can become a hot spot and lead to detonation. You could do it yourself with just a small piece of emery cloth and some light lubricant. Just work the area with the high spot(s) and try not to touch anywhere else on the chamber. You can put tape over the sections you don't want to touch and then start to smooth it out.

Yes, it will drop the compression but only by a minuscule amount that you would never notice and might not even be easily measurable by conventional methods.

Re: Smoothing out casting marks on kdx200 head

Posted: 12:11 am Jan 11 2024

by JZ05220r

SS109 wrote: 09:49 pm Jan 10 2024

Casting marks in the chamber itself? Weird. Got a pic?

If I could catch my fingernail on it I would smooth it out. Any edge can become a hot spot and lead to detonation. You could do it yourself with just a small piece of emery cloth and some light lubricant. Just work the area with the high spot(s) and try not to touch anywhere else on the chamber. You can put tape over the sections you don't want to touch and then start to smooth it out.

Yes, it will drop the compression but only by a minuscule amount that you would never notice and might not even be easily measurable by conventional methods.

Ok I might give it a try. It’s the entire surface as you can see that’s textured. Here’s a pic that I took while trying to measure the squish band width that shows the texture. Hopefully I’m getting my terminology correct when I say casting marks. There isn’t anything that I would consider an edge.

Re: Smoothing out casting marks on kdx200 head

Posted: 06:56 am Jan 11 2024

by John_S

That’s how they look from the factory. With everything you’ve been through, a perfectly running, reliable 200 with a stock head would be a beautiful thing. Bolt it up and let’s see if all of the other issues are gone. Most of the KDX’s out there that everyone praises over the years have been running that head.

Edit: I reread your 2nd sentence. My 220 head didn’t look perfectly smooth until I got it back from RB. It had the same micro stippled look that your 200 has. You’re too close to the project if you know what I mean. I deal with that at work where I’m worried about something that isn’t really an issue. Sweating the small stuff as they say.

Re: Smoothing out casting marks on kdx200 head

Posted: 08:03 am Jan 11 2024

by SS109

JZ05220r wrote: 12:11 am Jan 11 2024

Ok I might give it a try. It’s the entire surface as you can see that’s textured. Here’s a pic that I took while trying to measure the squish band width that shows the texture. Hopefully I’m getting my terminology correct when I say casting marks. There isn’t anything that I would consider an edge.

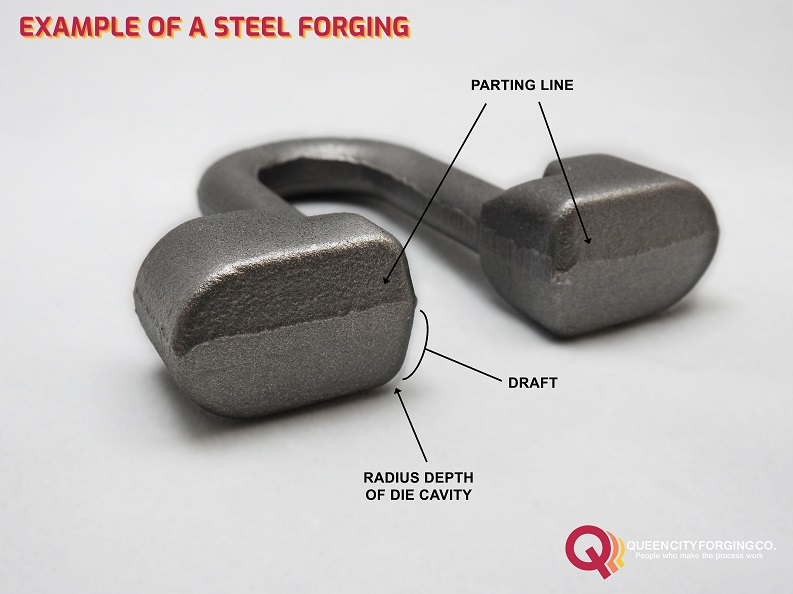

Yeah, I agree with John. That is just the factory casting and not anything to worry about. Leave it be, bolt it on, and go ride! Please disregard my first post completely. I thought you meant it had a casting line (a.k.a. parting line) in the chamber like in the pic below.

- ExampleOfSteelForging.jpg (106.74 KiB) Viewed 2820 times

Re: Smoothing out casting marks on kdx200 head

Posted: 01:39 pm Jan 11 2024

by JZ05220r

John_S wrote: 06:56 am Jan 11 2024

That’s how they look from the factory. With everything you’ve been through, a perfectly running, reliable 200 with a stock head would be a beautiful thing. Bolt it up and let’s see if all of the other issues are gone. Most of the KDX’s out there that everyone praises over the years have been running that head.

Edit: I reread your 2nd sentence. My 220 head didn’t look perfectly smooth until I got it back from RB. It had the same micro stippled look that your 200 has. You’re too close to the project if you know what I mean. I deal with that at work where I’m worried about something that isn’t really an issue. Sweating the small stuff as they say.

I get carried away, you’re right. Thanks

Re: Smoothing out casting marks on kdx200 head

Posted: 04:08 pm Jan 11 2024

by Chuck78

My stock chambered 220 heads look perfectly smooth except for a few detonation marks on one or two of them... Not like the textured casting pictured on James' 200 head.

My RB heads looks perfectly machined in contrast, whereas my stock chambered 220 heads look like a very smooth cast finish.

Re: Smoothing out casting marks on kdx200 head

Posted: 06:07 pm Jan 11 2024

by bufftester

Yeah, part of RBs squish band work involved reworking the head volume. My 220 head has the typical sand cast finish as well.

Re: Smoothing out casting marks on kdx200 head

Posted: 10:00 am Jan 12 2024

by Chuck78

bufftester wrote: 06:07 pm Jan 11 2024

Yeah, part of RBs squish band work involved reworking the head volume. My 220 head has the typical sand cast finish as well.

Yes, RB takes a fairly significant amount off the head gasket surface in order to create the sharp break at the edge of the squish band vs chamber dome (vs more rounded transition as stock), so in order to safely run 90 octane (USA octane rating), and also to keep peak cylinder pressures under the max 200psi-ish safe zone, the chamber volume needs cut to bring the total head volume back to near stock.