Page 1 of 2

preparing for plating

Posted: 08:50 am Mar 28 2009

by ogri

hiya fellas,hope your all well.i've decided to strip the top end of my bike ('00kdx220) and replate.i've removed the kips and the head studs and while cleaning the cylinder i discovered an allen plug directly below the exhaust port.should this be removed before i send it to the platers? if you are unfamiliar with this plug i will be happy to post a pic.

thanks.

Posted: 08:55 am Mar 28 2009

by Indawoods

All the platers will do is clean your cylinder and plate the bore... nothing else unless you are getting something fancy.

I do not know what you are talking about on the Allen Plug however....

Posted: 09:30 am Mar 28 2009

by ogri

i believe you have to remove all metalwork.so studs and kips removed,then i discovered this fella.

centre of exhaust post,hollow allen plug.

hopefully its of no consequence but i got the idea all metalwork had to be removed prior to the processes the barrel undergoes.

Posted: 04:34 pm Mar 28 2009

by Little Jeff

Who is going to be doing the replating?

Little Jeff

Posted: 07:13 pm Mar 28 2009

by MXOldtimer

Might as well punch it out a little more if your going to plate it.

Posted: 07:35 am Mar 29 2009

by ogri

Little Jeff wrote:Who is going to be doing the replating?

Little Jeff

i live in the uk jeff.a company called langcourts has a great reputation for their work.anyone want to comment about the stud?presumably posters here have left it alone.

Posted: 08:28 am Mar 29 2009

by Julien D

I think you'll be fine leaving that plug in place. I've heard good things about langcourt as well. Make sure to post some pictures of the finished cylinder when you get it back from plating.

J.

Posted: 09:54 am Mar 29 2009

by fuzzy

I dont think langcourt will do anything with the ports if you request a bore increase, and increasing bore will alter port timing. In a bad way? Dunno.

Looks just like a freeze/casting plug...No need to mess with it for replate.

Posted: 01:14 pm Mar 29 2009

by ogri

just want a replate fellas.thanks for the replies,pot going to langcourts tomorrow.i'llpost a pic on its return juliend.

Posted: 01:50 pm Mar 29 2009

by MXOldtimer

You'll want to buy a new piston prior plating. They will mic the new pistons and make sure the tolerances are correct before/after plating.

Posted: 10:59 am Mar 30 2009

by canyncarvr

That plug's in the water jacket, ain't it? The best source for the correct answer is Langcourt. As unnecessary as removal of a water jacket plug would seem to me...I'm not doing the work. For all I know the electrical charges involved in a replate job fuses all separate metal parts!

Langcourt has a good reputation on this side of the puddle, too.

Don't forget some pics of the finished product!!

Thanks!

Posted: 11:54 am Mar 30 2009

by sean-svm

Don't loose that plug as it is not a part you can buy new from Kawasaki.

Posted: 08:22 am Apr 01 2009

by ogri

sean-svm wrote:Don't loose that plug as it is not a part you can buy new from Kawasaki.

hopefully langcourts will leave it in place.if they do remove it i'll make sure its returned to me.

thanks for the replies gents.

Posted: 05:00 pm Apr 22 2009

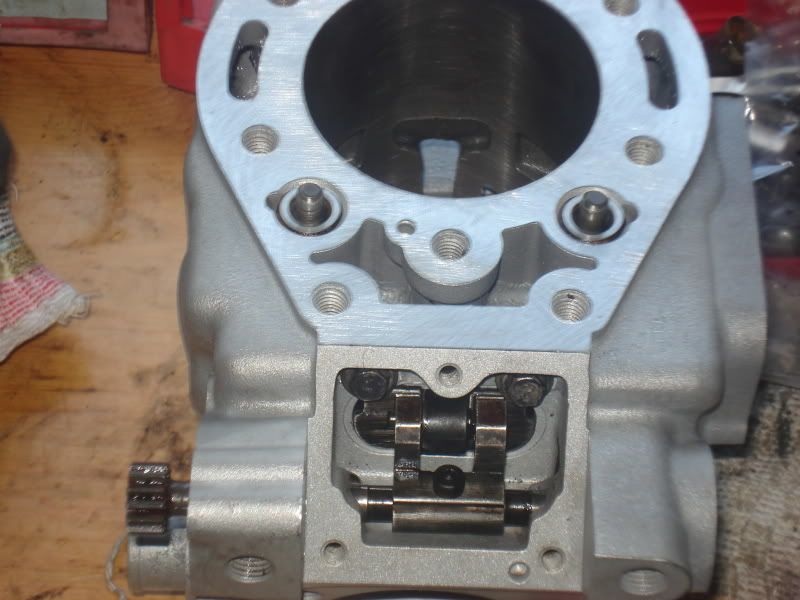

by ogri

Posted: 06:37 pm Apr 22 2009

by canyncarvr

So...where are the plugs for the subport drum rods?

Seems odd they would replace the one..but not those?

Posted: 10:54 am Apr 23 2009

by fuzzy

Wow, did they true up the deck?

Posted: 11:25 am Apr 23 2009

by KarlP

Check to be sure the right hand subport actuating rod moves smoothly in its bore......

That rod has a o-ring/packing/seal on it that keeps ehaust gasses from blowing by. The plating process can leave the inside of that bore rough and the rod can therefore not move as smothly as it needs to.

The whole KIPS mechanism should move smooth as silk..

Posted: 05:19 am Apr 24 2009

by ogri

KarlP wrote:Check to be sure the right hand subport actuating rod moves smoothly in its bore......

That rod has a o-ring/packing/seal on it that keeps ehaust gasses from blowing by. The plating process can leave the inside of that bore rough and the rod can therefore not move as smothly as it needs to.

The whole KIPS mechanism should move smooth as silk..

karl,it was rough in there.the left had rod went in easily.i had to clean the right side casting out.i wish now that i had been more thorough as the actuation of the kips felt a little stiffer than before the rebuild.

Posted: 05:22 am Apr 24 2009

by ogri

canyncarvr wrote:So...where are the plugs for the subport drum rods?

Seems odd they would replace the one..but not those?

if you mean those allen caps plugging the rods in,i removed those.

tried it out today and everything appears fine.should i re-torque the head now its cooled down?

Posted: 10:00 am Apr 27 2009

by KarlP

I don't think you need to re-torque the head bolts.

Have you observed smooth operation of the KIPS mechanism while the motor is running?

The left hand slotted cover provides a convenient way to do that.