Page 1 of 1

Pictures of the Inside of a New KDX Cylinder (For Reference)

Posted: 11:48 pm May 15 2020

by KDXGarage

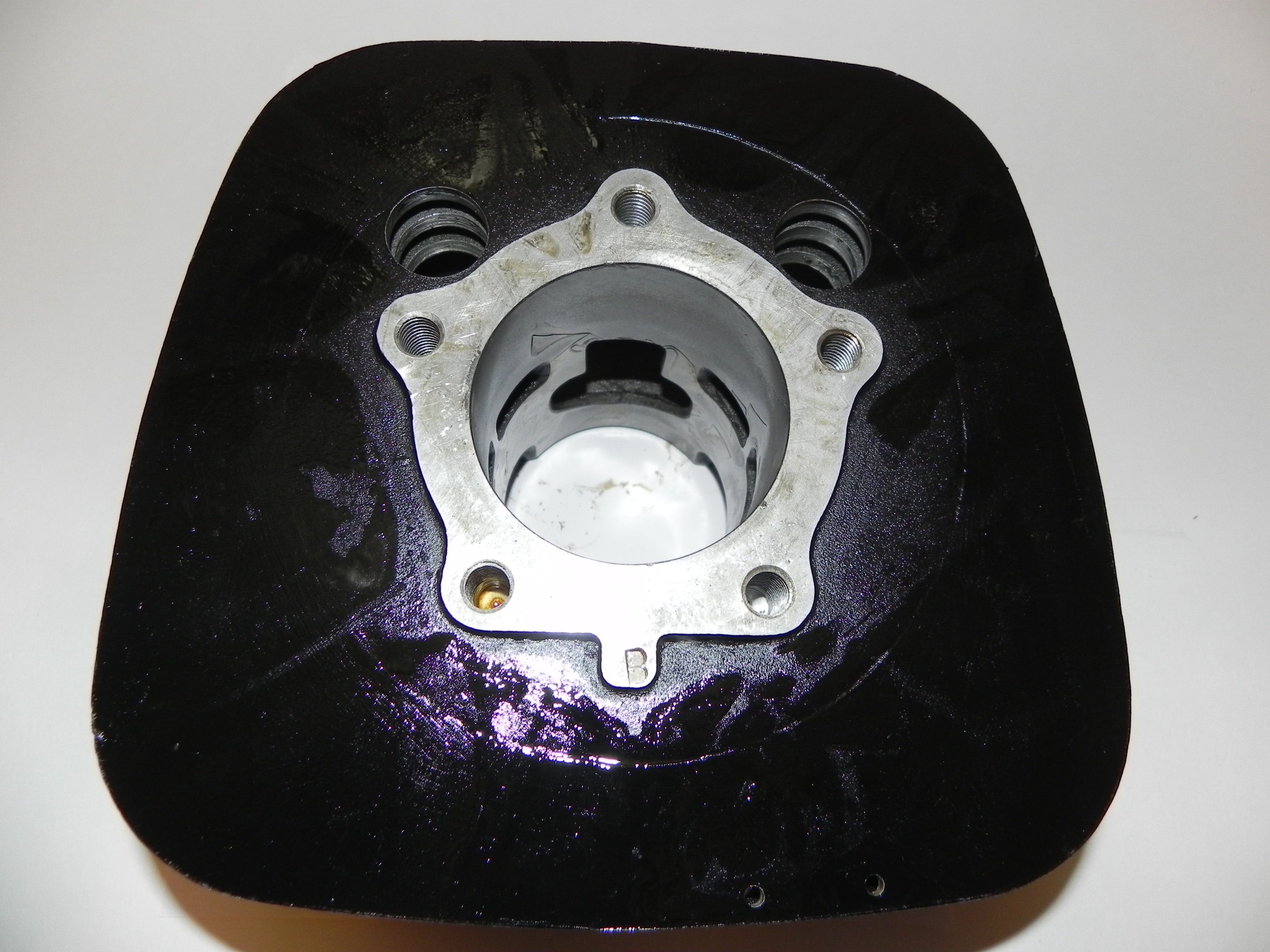

Here are some pictures of a NOS KDX175 cylinder I had. Please note that the finish is smooth, without cross-hatching that some may see on aftermarket plating or other non-Electrofusion OEM cylinders. Over the years, I have read MANY posts from people on the internet stating that someone posting pics of an Electrofusion cylinder has a completely worn out cylinder. "All the cross-hatching is worn off.", etc.

I have a new 1989 - 1994 KDX200 cylinder that is the same as this one.

This cylinder has Kawasaki's brown preservation oil on it, so it looks like stains or something on the surface.

One can open the images in a new window to see them MUCH larger.

Thanks.

- DSCN2443.JPG (3.34 MiB) Viewed 2292 times

- DSCN2445.JPG (3.7 MiB) Viewed 2292 times

- DSCN2446.JPG (3.53 MiB) Viewed 2292 times

- DSCN2448.JPG (3.29 MiB) Viewed 2292 times

Re: Pictures of the Inside of a New KDX Cylinder (For Reference)

Posted: 12:24 am May 16 2020

by SS109

Man, it looks worn out!

Thanks for posting it up. That is some good reference material as I know I'm guilty of the "it looks worn out" statement" at times. It's really hard to tell from pics if an electrofusion cylinder is actually worn out. Of course, considering the newest KDX is 15 years old now, it is a fairly safe assumption that most are due for a replate.

Re: Pictures of the Inside of a New KDX Cylinder (For Reference)

Posted: 12:45 am May 22 2020

by '03KDX200

KDXGarage wrote: 11:48 pm May 15 2020

Here are some pictures of a NOS KDX175 cylinder I had. Please note that the finish is smooth, without cross-hatching that some may see on aftermarket plating or other non-Electrofusion OEM cylinders. Over the years, I have read MANY posts from people on the internet stating that someone posting pics of an Electrofusion cylinder has a completely worn out cylinder. "All the cross-hatching is worn off.", etc.

I have a new 1989 - 1994 KDX200 cylinder that is the same as this one.

This cylinder has Kawasaki's brown preservation oil on it, so it looks like stains or something on the surface.

One can open the images in a new window to see them MUCH larger.

Thanks.

Ah, this is interesting. Thank you for posting these pics. It is good to see what a new/super fresh cylinder looks like. I have a couple questions!

1) You would always want a cross-hatch type of hone on any type of new or refurbished cylinder, electroplated or not, wouldn't you? Are there exceptions , where you'd want a totally glossy finish the in the cylinder?

2) I have the 2nd gen/H model KDX 200 (2003). Is my cylinder supposed to be plated? Was it plated from the factory? Is there an option or advantage of going with a non-plated cylinder?

Re: Pictures of the Inside of a New KDX Cylinder (For Reference)

Posted: 03:15 am May 22 2020

by KDXGarage

Any Kawasaki made USA KDX cylinder pretty much looks like above when new. 1974 KX125 had the Electrofusion coating, so they were doing it 5 years before any KDX. They call it a coating instead of a plating. It is applied a little differently, but the end result is similar. It's a thin, hard layer on the surface, instead of a steel / iron liner.

Re: Pictures of the Inside of a New KDX Cylinder (For Reference)

Posted: 06:56 pm May 22 2020

by '03KDX200

KDXGarage wrote: 03:15 am May 22 2020

Any Kawasaki made USA KDX cylinder pretty much looks like above when new. 1974 KX125 had the Electrofusion coating, so they were doing it 5 years before any KDX. They call it a coating instead of a plating. It is applied a little differently, but the end result is similar. It's a thin, hard layer on the surface, instead of a steel / iron liner.

Ah ok. Cool then ALL KDX 200/220's had electroplated/coated cylinders. So we can just assume when we have someone refurbish a cylinder for us, we'll need to pay the extra $200 or so to have it sent to an electroplating place.

Re: Pictures of the Inside of a New KDX Cylinder (For Reference)

Posted: 07:36 pm May 22 2020

by KDXGarage

Not necessarily. People running rings and pistons for years will tear up ANY company's plating / coating.