I built my own tester from parts from Amazon (parts list below). It took a couple days to get it built because I was threading a NPT hose barb into a thin freeze plug. I knew that there was no way that was going to seal, so I applied a little 3M 5200 that I had stored in the freezer. Normally, it takes 48 hours to cure. It never cured, maybe from being frozen, so I had to start over.

Today, I applied some epoxy and got it cured enough to use. On the first pump up to 6 psi, the gauge dropped and I could hear hissing from around the intake. I brushed some soapy water around the rubber intake and reed block and had bubbles coming out pretty much from all around it.

Between the metal reed block and cylinder, I had put in a new gasket with Gascacinch on one side and grease on the other side of the gasket material. In between the reed block and rubber boot, there is nothing but a molded in o-ring type shape. It obviously was not doing its job. I applied a bead of Ultra Copper, hand tightened the bolts, and waited a couple hours before torquing to spec.

Next pump up with the gauge, I lost about a half pound in 15 minutes. I thought that might be good enough, but I'm sure I would have been troubled about it. I started with the soapy water again, starting with the Kips resonator, and lo-and-behold, there were a couple bubbles. I pulled the cover off and realized that I had not applied grease to the one side of the gasket. After wiping on grease and reassembling, the next pressure test held 6 pounds for an hour!

I am so glad I did this and recommend this to anyone doing a top or bottom end. I feel that I now have a stable platform for carb tuning along with much less chance of seizing.

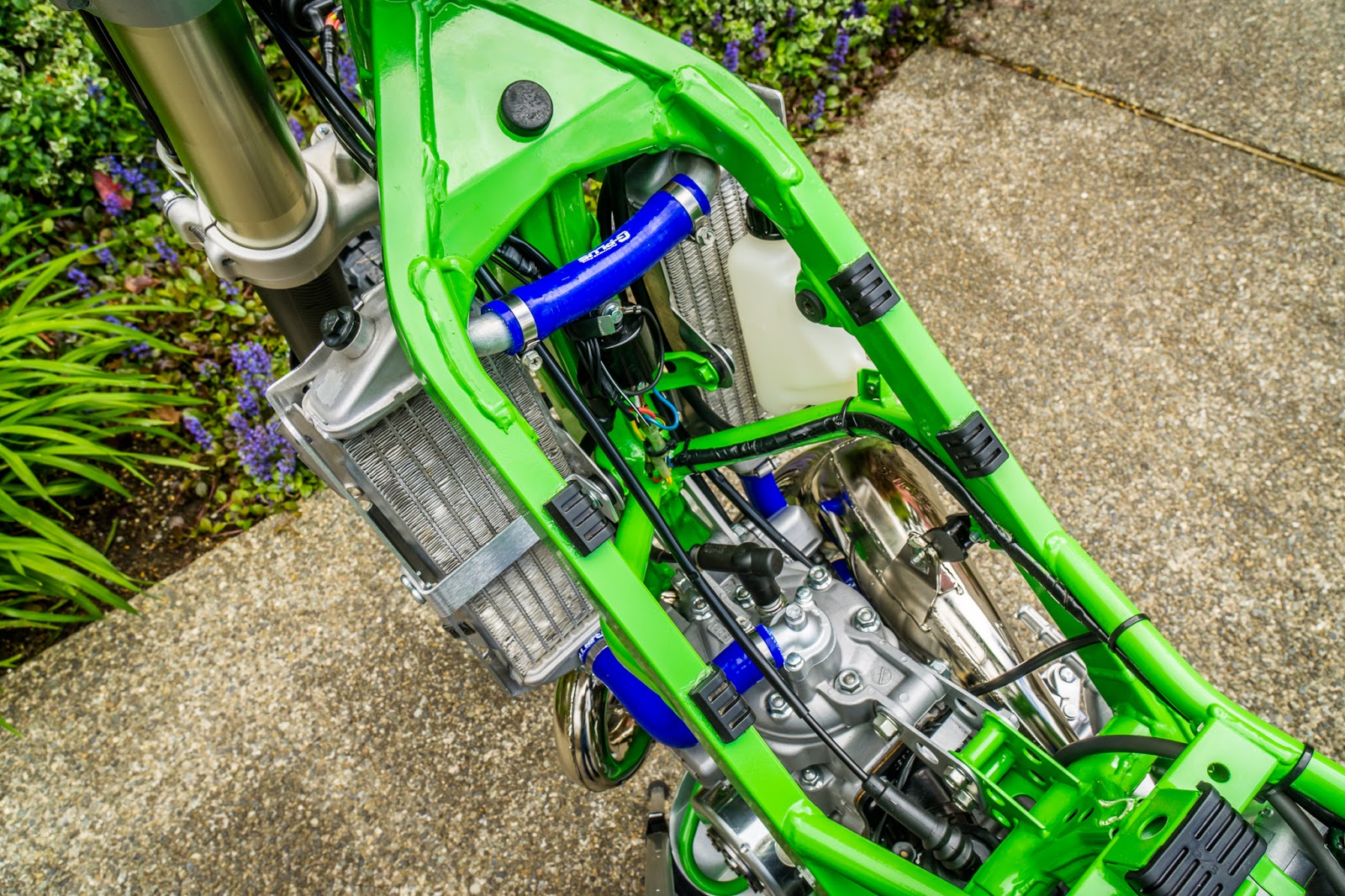

Time for the engine to go into the frame!

(For plugging the exhaust - you can get these individually at a auto parts store)

(For plugging the intake - sold individually at an auto parts store. I drilled this for the hose barb)