Thank you Ted! I turned 27....awfully close to 30...feeling old

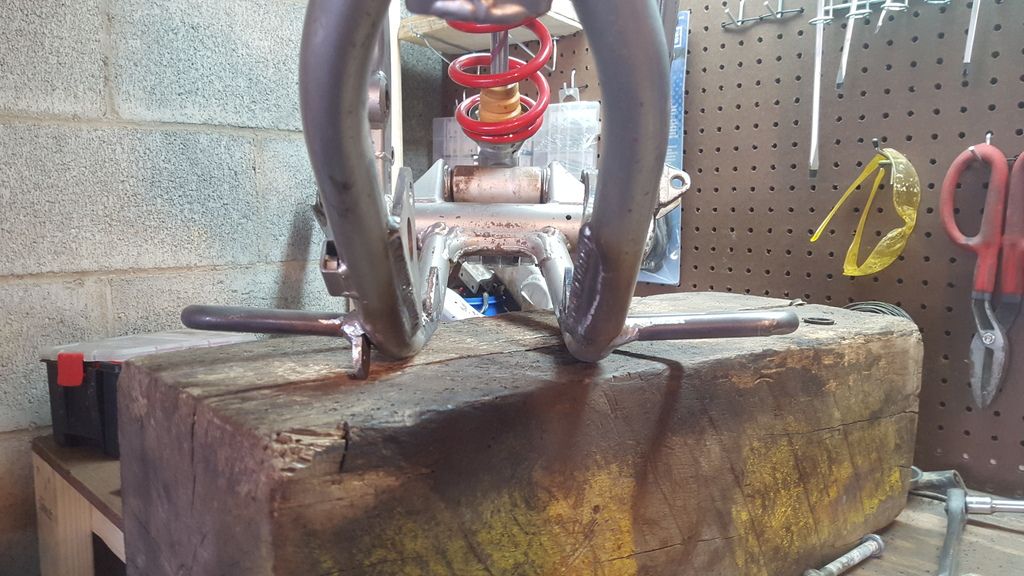

We got the motor mounts finished up, adjusted the CDI mount location, moved a pipe mount, and made a new pipe mount. My dad re-created the KDX frame hoops at work yesterday, plan to get those on one day this week. After that I can tear down and start powder coating it. The plate we used for the mounts was a bit heavier than I wanted to use, but it was free so I can't complain. As long as the welder knows where to focus the heat, shouldn't be an issue (I had a pretty good welder on my side lol 30+ years experience).

I also was a bit unsure about my wheels, being the first time that I ever actually laced and trued a set. So I broke down and got one of those spoke torque wrenches. I can now confidently say that all of the spokes are at least 40 in-lbs, the wheels have .020" or less runout in all directions, and they should be ready for tires

Here are some photos... I have some questions about some things I ran into, please see the bottom:

1. The coolant line that exits just above the motor on the right side. Any good ideas how to address this? I ended up using the KX hose right off of the radiator, then spliced into the KDX hose about halfway down. I don't have any photos, but it seems to fit nicely when the pipe is on and everything. I didn't know if I could use a complete hose off of something else here?

2. With everything together, the silencer doesn't fit completely into the pipe. Is there a way to create a reliable seal between the silence and pipe without having full engagement? Or should I be looking at modifying the mounts for the silencer? I am using an 05 KX250 silencer. I was thinking about making a plate out of aluminum to offset the mounting pipe mounting holes further back, allowing for full engagement between the two pieces.

3. For the lower pipe mount, we welded a tab onto the frame. The plan was to run a bolt thru the pipe tab and into the tab on the frame, meaning the bolt would go straight across, horizontally. I planned to put a piece of rubber hose over the bolt between the two tabs to allow it to absorb some vibration. Am I asking for trouble having a pipe mount like this? I know that all of the factory mounts have those rubber hangers that allow the pipe to "hang" rather than be bolted straight to something. I don't know if I am explaining it well enough, hopefully the photos will help to explain better. I wanted to re-use the factory style pipe hanger there but couldn't get a spot for the tab on the frame where that wouldn't interfere with the pipe.

4. I wanted to run the KX125 kicker. It looks like that is going to interfere with the pipe too much, so I ditched that idea. I hate the KDX kicker, so that is my last resort. I got a KX250 kicker and it almost works, just wants to hit the frame a little when its turned in. Anyone else deal with that? It doesn't seem like that big of a deal, I was thinking about putting a piece of rubber hose on the corner of the lever where it contacts the frame. Then wrap it up real good with some self fusing tape, should isolate the vibration?

I think those are my biggest concerns at this point that I would like to try to figure out this week before starting to prep for powder. Any input you could provide would be much appreciated!