Page 8 of 8

Re: Kips sub shaft o-ring

Posted: 09:57 pm May 29 2025

by Kawibunga

OK - so I finally had some time to engineer nerd out here. The drawing below has all the info and measurements I have. Use at your own risk obviously. But my plan is to modify the groove diameter as per the drawing and give it a go! I also compare used stock measurements to Fredette's oring and to the 008 Xring. My take is use the Fredette's solution, or the Xring, or keep searching for the unicorn packing. Mine will be in the machinists hands tomorrow. If any one is interested, I'm happy to share the SolidWorks files, or as STL / STEP files, and the actual PDF of this drawing. Just PM your email and I'll fire it off............ Cheers - Robert

Re: Kips sub shaft o-ring

Posted: 10:04 pm May 29 2025

by Kawibunga

- KDX Packing Info.JPG (149.72 KiB) Viewed 39576 times

Re: Kips sub shaft o-ring

Posted: 01:13 pm May 30 2025

by Chuck78

Excellent work! Thank you, sir!

Re: Kips sub shaft o-ring

Posted: 06:32 pm May 30 2025

by billie_morini

Kawibunga. that's a neat summary drawing. Thank you! Curious to hear any feedback from the machinist that will cut the groove.

Re: Kips sub shaft o-ring

Posted: 02:08 pm May 31 2025

by Kawibunga

billie_morini wrote: 06:32 pm May 30 2025

Kawibunga. that's a neat summary drawing. Thank you! Curious to hear any feedback from the machinist that will cut the groove.

The young fellow picked it up yesterday. Said it shouldn't be a problem. Their standard narrow cutter is 1/16" and the groove width is .080" so it shouldn't take any special tools. Will post how it all turns out. Just going cost me beer and chicken wings!

Re: Kips sub shaft o-ring

Posted: 02:14 pm May 31 2025

by KDXGarage

Thanks for the update!

Re: Kips sub shaft o-ring

Posted: 11:30 am Jun 02 2025

by Chuck78

Kawibunga wrote: 02:08 pm May 31 2025

billie_morini wrote: 06:32 pm May 30 2025

Kawibunga. that's a neat summary drawing. Thank you! Curious to hear any feedback from the machinist that will cut the groove.

The young fellow picked it up yesterday. Said it shouldn't be a problem. Their standard narrow cutter is 1/16" and the groove width is .080" so it shouldn't take any special tools. Will post how it all turns out. Just going cost me beer and chicken wings!

I'm going to bet that my parting tool bit (tall skinny cutoff tool steel bit for lathe use in cutting off a section from the end of a lathe turned work piece) will do nicely. I'll probably finish it off with a piece of emery cloth folded in a U-shape to deburr/polish it.

Re: Kips sub shaft o-ring

Posted: 01:49 pm Jun 30 2025

by jamiethegiraffe

Kawibunga, that technical drawing is awesome. thank you for taking the time to make it!

I just wanted to stop by and say my ebay 5x8 red silicone O ring is still holding up. I think it has about 40 hrs on it now and has seen some really high coolant temps and hard running in muddy enduros. I'm tearing the motor down due to a crank seal leak, but the Fredette-inspired economy fix is still holding back air pressure when leak tested @ 5 psi. No visible wear or marring on the O ring.

I've recently acquired a few O rings of the same size made from buna. I will probably try one of these out when i reassemble the engine, but so far the silicone seems totally adequate.

Re: Kips sub shaft o-ring

Posted: 06:51 pm Jul 01 2025

by Chuck78

Thanks for the report back, Jamie! I will be putting in one of these o-rings after Friday morning's ride when I tear my top end down for inspection, cleaning, piston ring and Gap measuring, and cylinder bore measuring...

Re: Kips sub shaft o-ring

Posted: 01:12 am Jul 02 2025

by billie_morini

jamiethegiraffe wrote: 01:49 pm Jun 30 2025

Kawibunga, that technical drawing is awesome. thank you for taking the time to make it!

I just wanted to stop by and say my ebay 5x8 red silicone O ring is still holding up. I think it has about 40 hrs on it now and has seen some really high coolant temps and hard running in muddy enduros. I'm tearing the motor down due to a crank seal leak, but the Fredette-inspired economy fix is still holding back air pressure when leak tested @ 5 psi. No visible wear or marring on the O ring.

I've recently acquired a few O rings of the same size made from buna. I will probably try one of these out when i reassemble the engine, but so far the silicone seems totally adequate.

Thank you, Jamie Giraffe. This is good news from someone that understands performance and bench testing.

Re: Kips sub shaft o-ring

Posted: 06:37 pm Feb 07 2026

by Chuck78

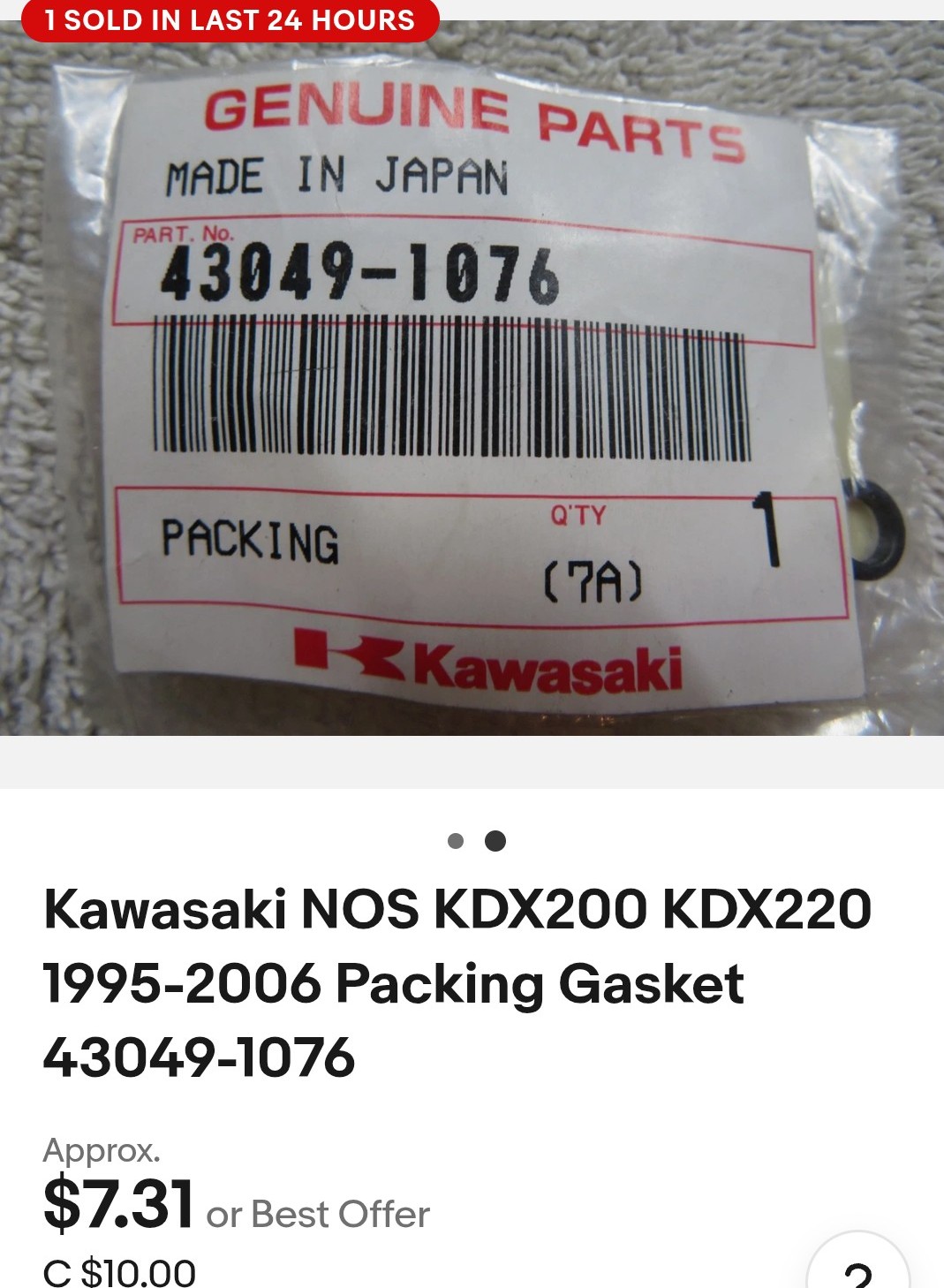

While the dimensions were on here as measured on at least 3 different NOS and used KIPS packing seals, as measured by at least 2 different forum members, I've had the part # on my eBay saved search alerts for ages now, & one just popped up NOS in OEM packaging from a dealer in Canada, & I decided to jump on it in order to get my hands on an unused one for my own references.

- KIPS-packing_seal1.jpg (231.03 KiB) Viewed 4295 times

- KIPS-packing_seal.jpg (107.16 KiB) Viewed 4295 times

I have several of the silicone o-ring substitutions to use, which were graciously sent to me by no less than TWO different generous forum members participating in this thread, as they typically are so low priced that you must order a minimum quantity of them for the sellers to make any profit. Thanks Jamie & Billie! This NOS packing seal that I should have from Canada soon may just remain a reference piece.

https://www.ebay.com/itm/366182522502

In looking up this thread, I happened upon a 2007 thread from the infamous CanyonCarver,,

viewtopic.php?t=3727

where he said he ordered two of these on an OEM parts order through his local Kawasaki dealership, but instead, received 2 separate smaller X-rings per each single KIPS packing seal ordered...???!!!

REALLY? So Kawasaki may have briefly been substituting two off-the-shelf X-rings to replace one single packing seal...??? This is perhaps the biggest news on this whole 6 or 8 page thread on this part number in my view at least... Now, if we only could have gotten dimensions off of Kawasaki's substitution part before they just simply listed them as NLA?!

Perhaps there was some sort of service bulletin on this that would still be able to be be looked up in Kawasaki databases???

canyncarvr wrote: 04:12 pm Jan 18 2007

...I just ordered the OEM stuff.

What I just got? O-rings! NOT what the bike came with! They are

special O-rings, though. They look like X-rings on a chain..but the 'relief' or cut is on the outer diameter as opposed to a lateral diameter.

Re: Kips sub shaft o-ring

Posted: 10:33 pm Feb 07 2026

by billie_morini

Chuck, you're a god! You got one! I never even knew there was such an alert system in Ebay! I'd prolly keep it for reference, too. I might also use it's dimensions with entities like Fredette or China manufacturer to ascertain whether somebody would make new ones. I wonder if Enduralast or Caltric would make them.

But, Chuck. What I'm really trying to say is, "Gee, can I borrow it? Just for a little while. I promise to take good care of it. Honest."