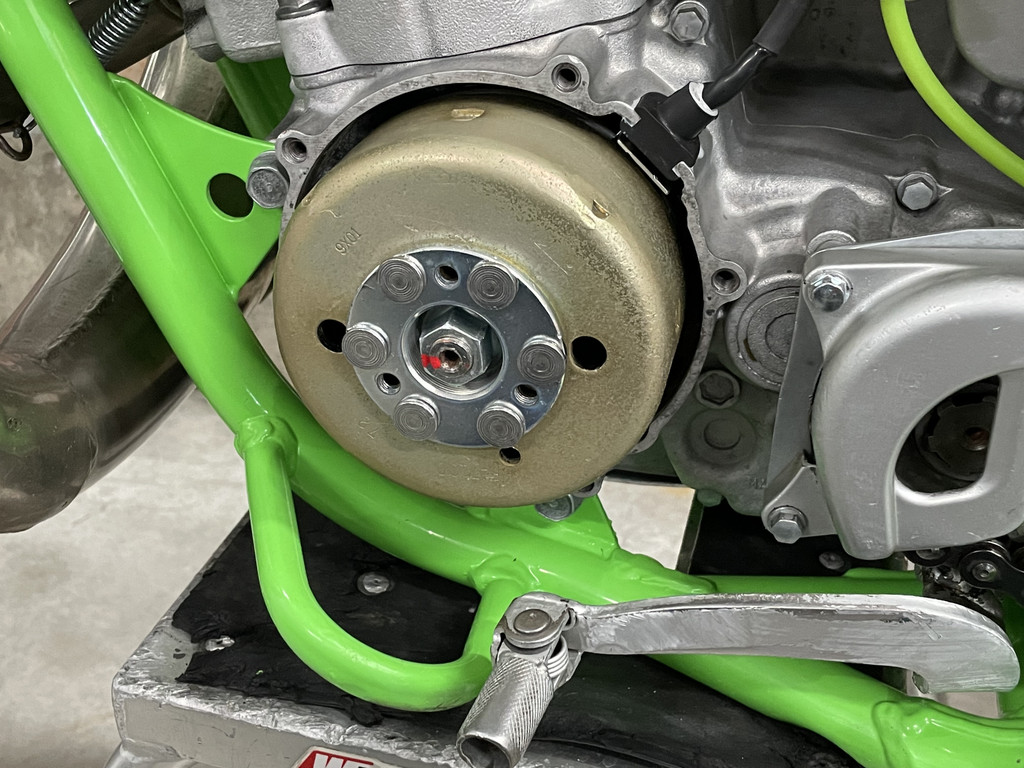

My stock exciter coil was just barely outside of the factory tolerance, and since I wanted to rewind my lighting coil anyways, I figured it was as good a time as any to try my hand at the exciter coil too. I couldn't find any information on the wire used for the stock coil, but I figured I would go with the finest I could procure, so if anything it would have a higher output than stock. I'd rather have too much spark, than not enough, however one must be careful not to go too far overboard.

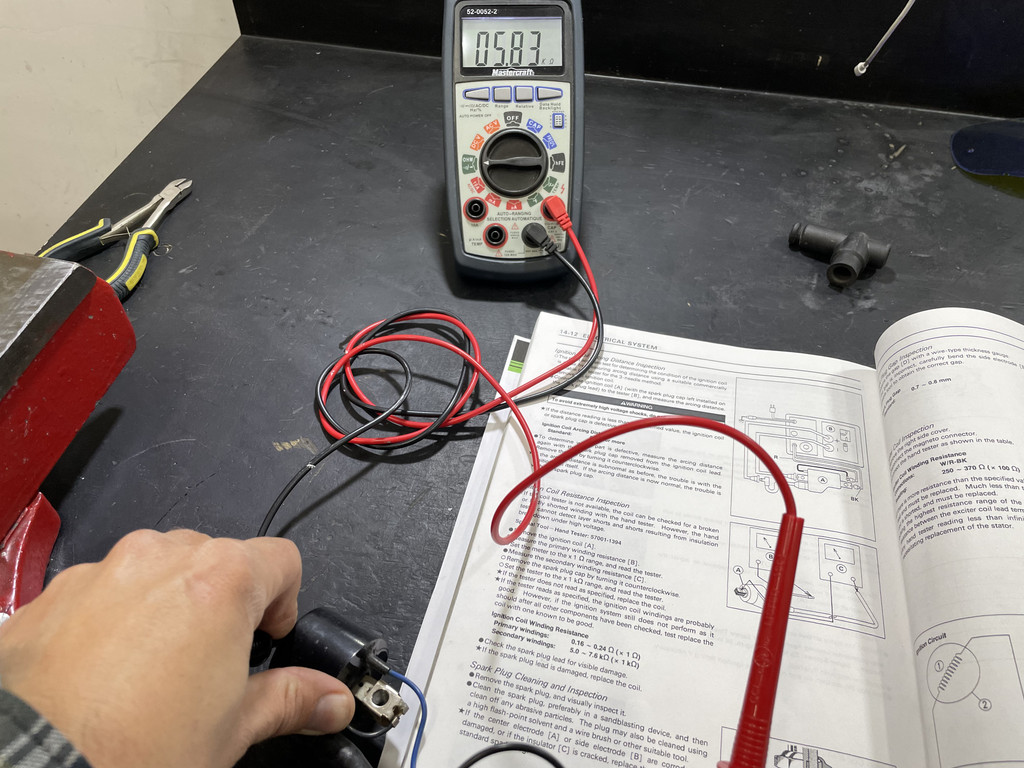

I have never done this rewind before. This is an experiment for me. I took some "educated guesses" on wire gauge, winding procedure, etc, but the only way to know if this will work will be to try it out. I have a new ignition coil coming today.

In theory, a higher voltage stator will produce a better, stronger spark at lower RPM, making the bike easier to start. However, there are a few considerations:

- I couldn't find any specs on the stock CDI, in terms of what it can handle in input voltage. 400v? 700v? I don't even know what the stock winding outputs at higher RPM. A winding that's "too good" could fry the stock CDI at higher RPM.

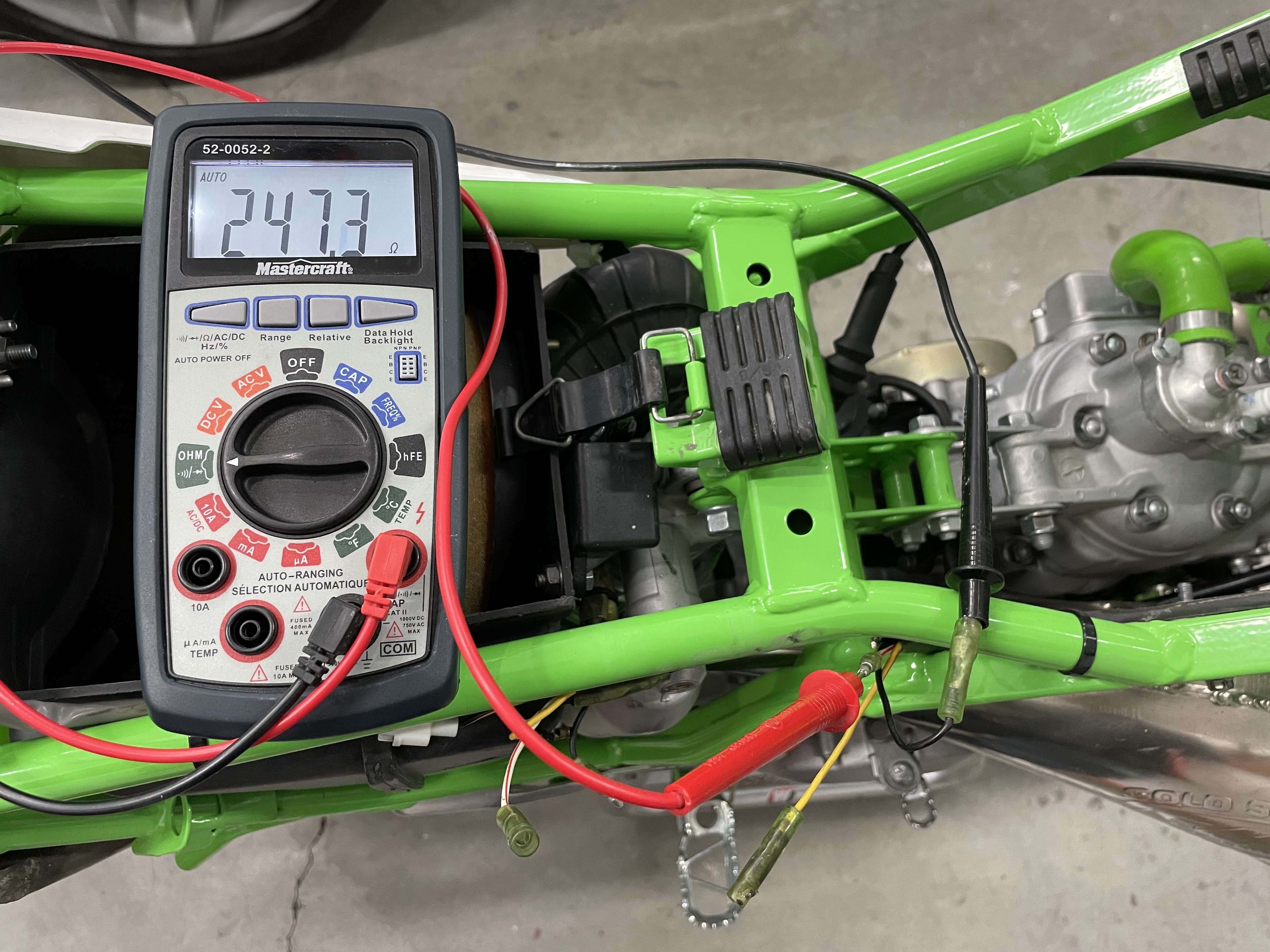

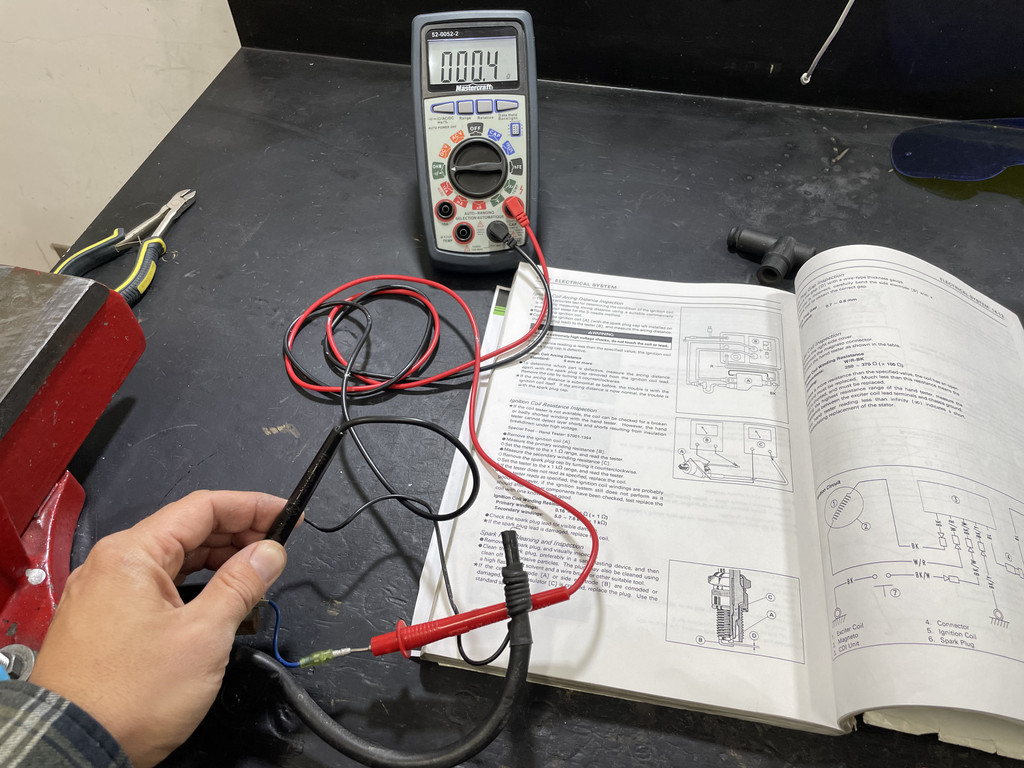

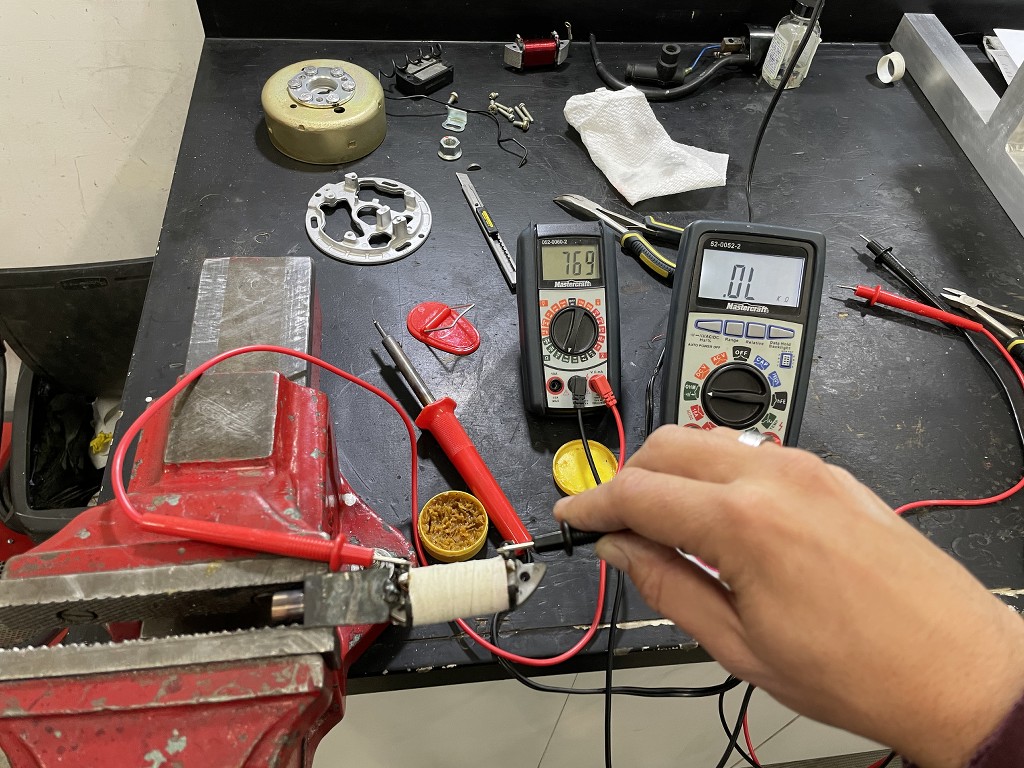

- More windings of a thinner wire will mean more resistance when measured. This will need to be noted, as the factory spec is only good for a factory winding. If I ever want to diagnose my winding in the future, I'll need to refer to my "known good" spec of when I just rewound it.

Onto the process:

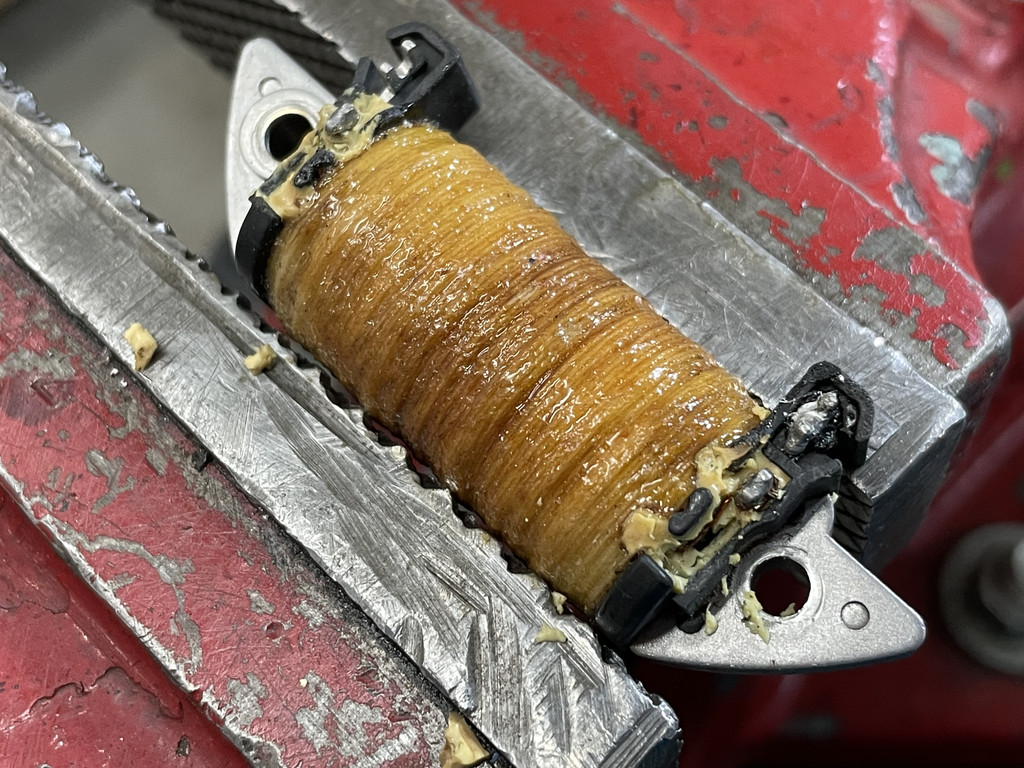

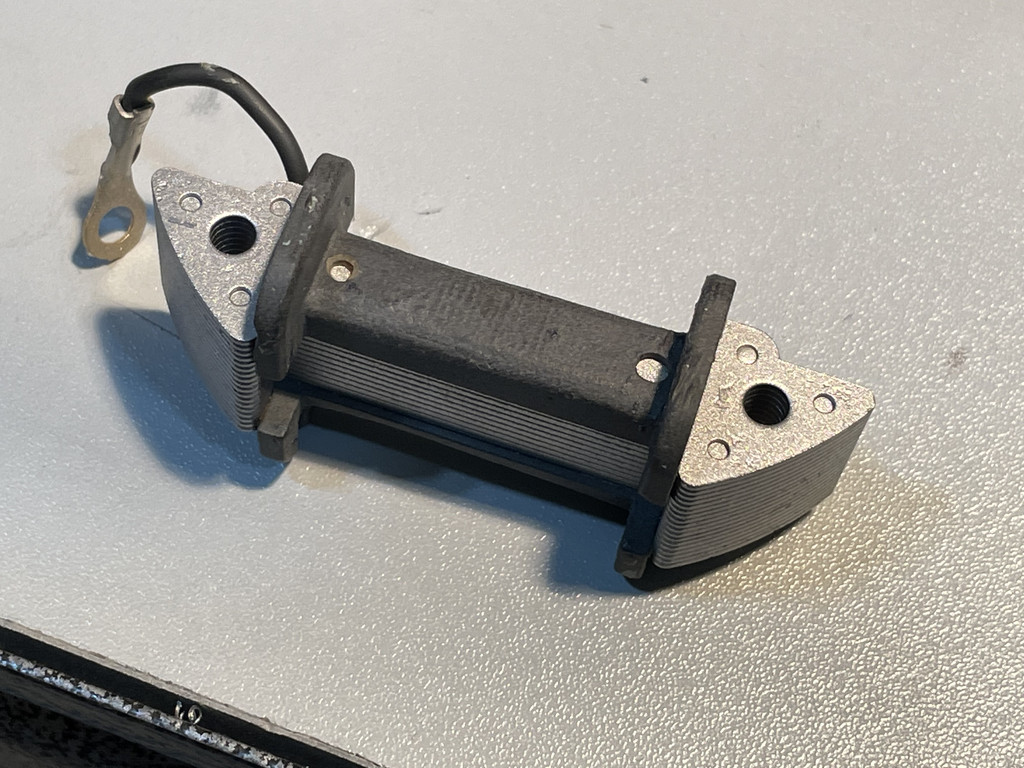

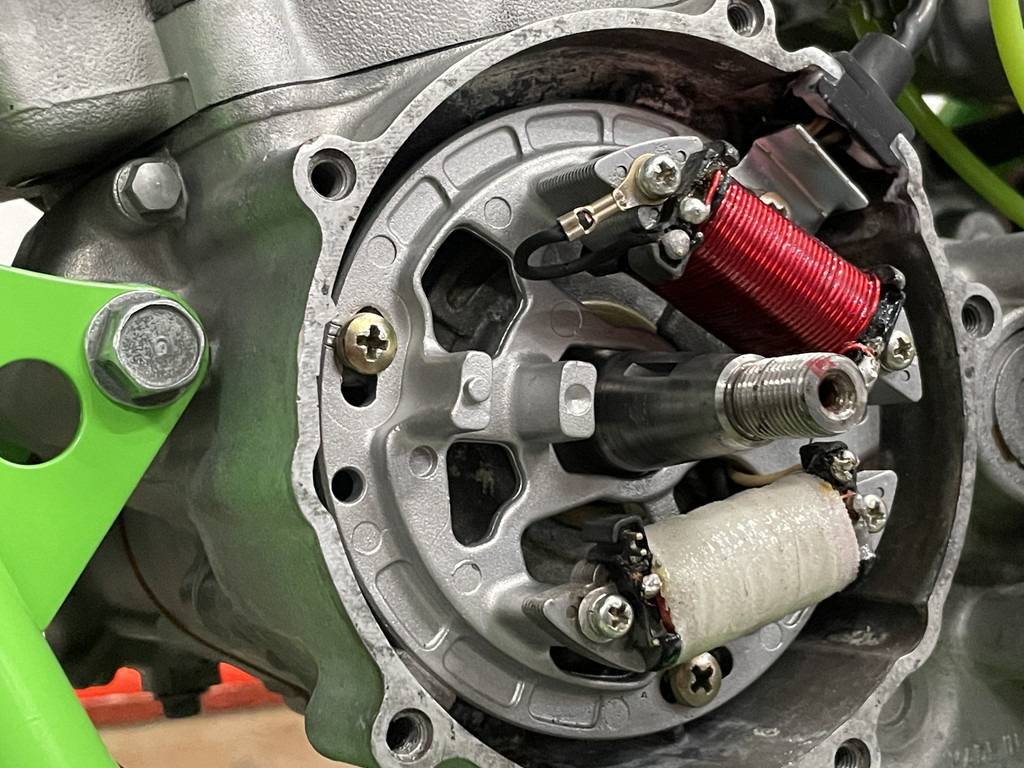

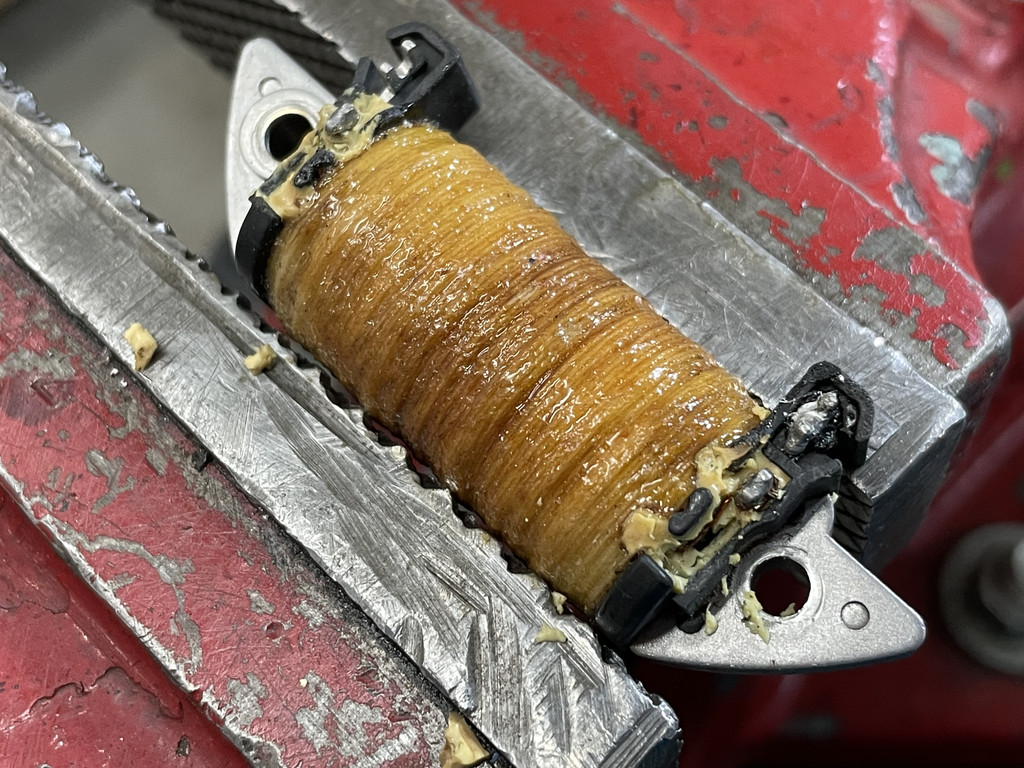

First, the stock stator must be disassembled. This is a colossal pain in the ass. There are a LOT of wires encapsulated in a hard epoxy, with pesky bits of silicone over the terminals.

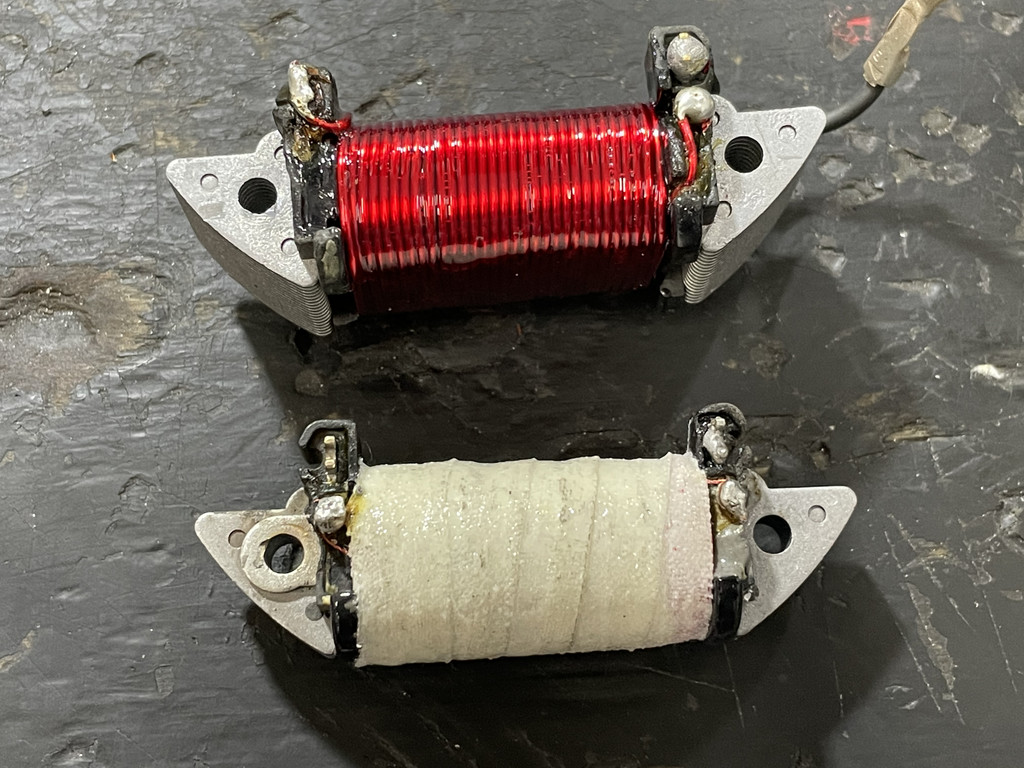

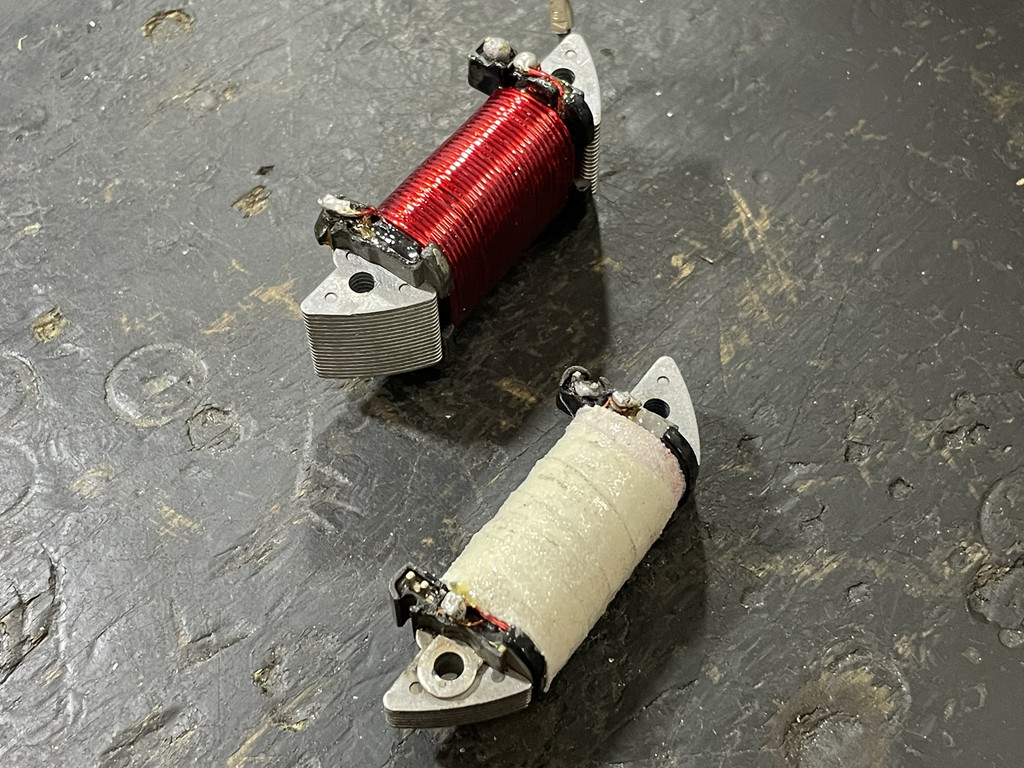

With the wire removed, I cleaned up the plates in the bead blast cabinet. This was a bad idea. The stock plastic "cage" basically disintegrated. It's not hard plastic, or at least not anymore after 22 years of service. It was almost like a dried sort of play-doh consistency. It flaked off easily with my fingernail. Looking online, most rewinds are done by wrapping the core and sides with cardboard, I didn't like this route, so I made a small repair to the one side plate with JB, and wrapped the core with thin tape. All we need is a barrier from abrasion around the core.

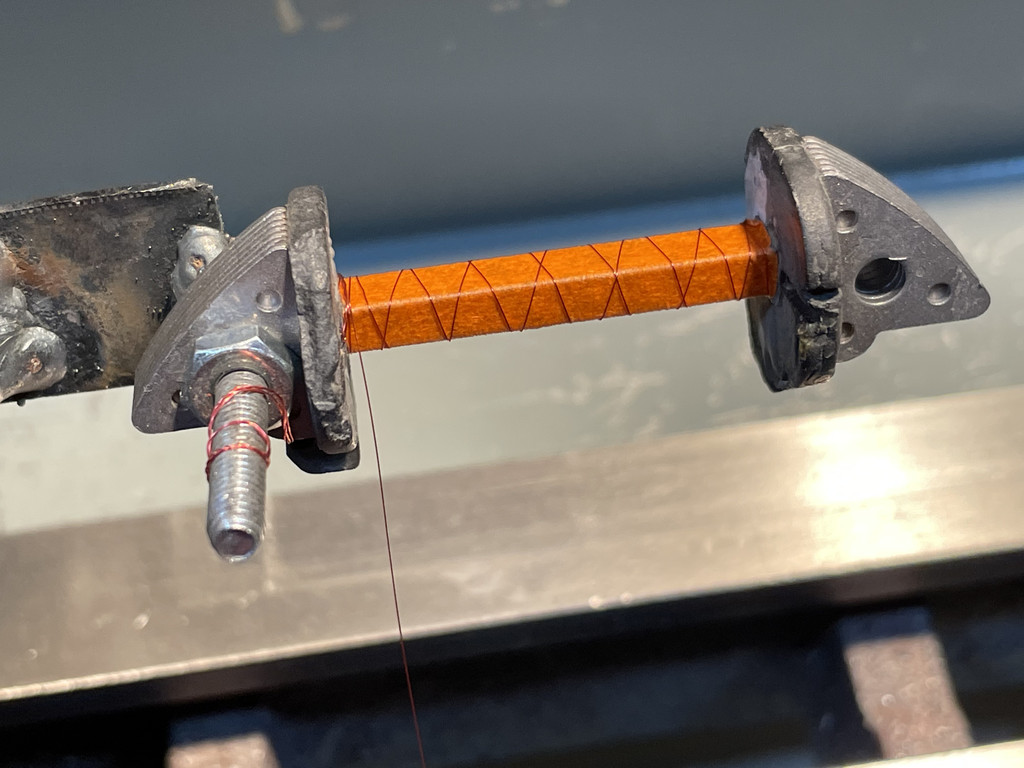

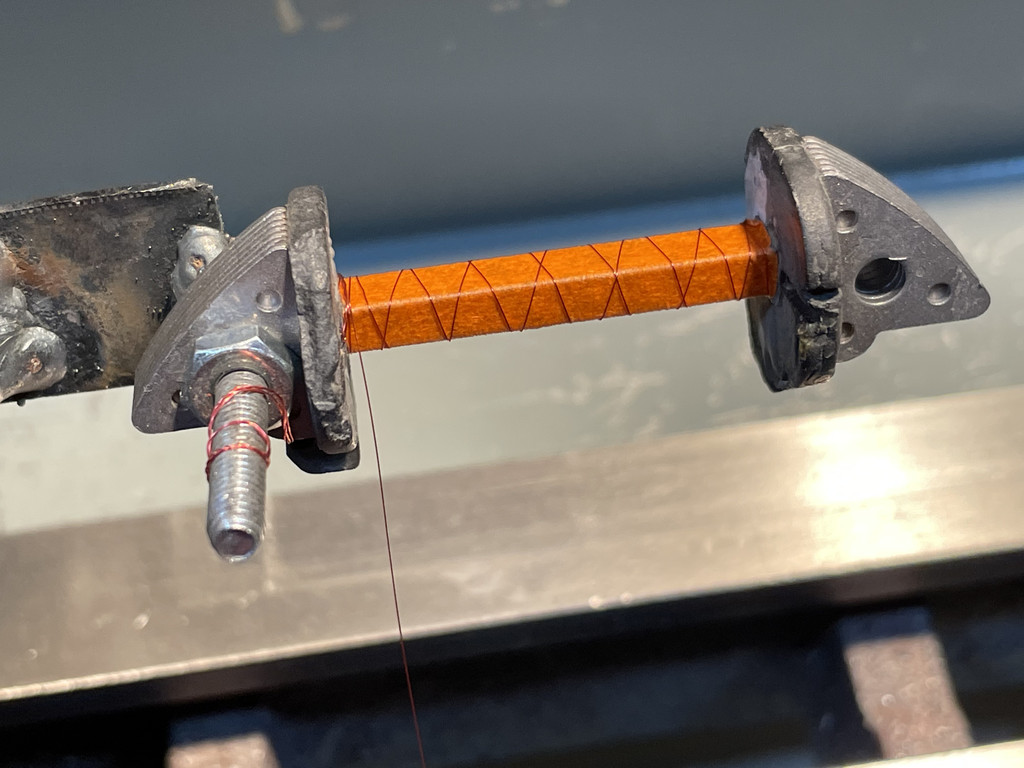

I quickly welded a tiny fixture to hold the stator in my little lathe, and got to winding.

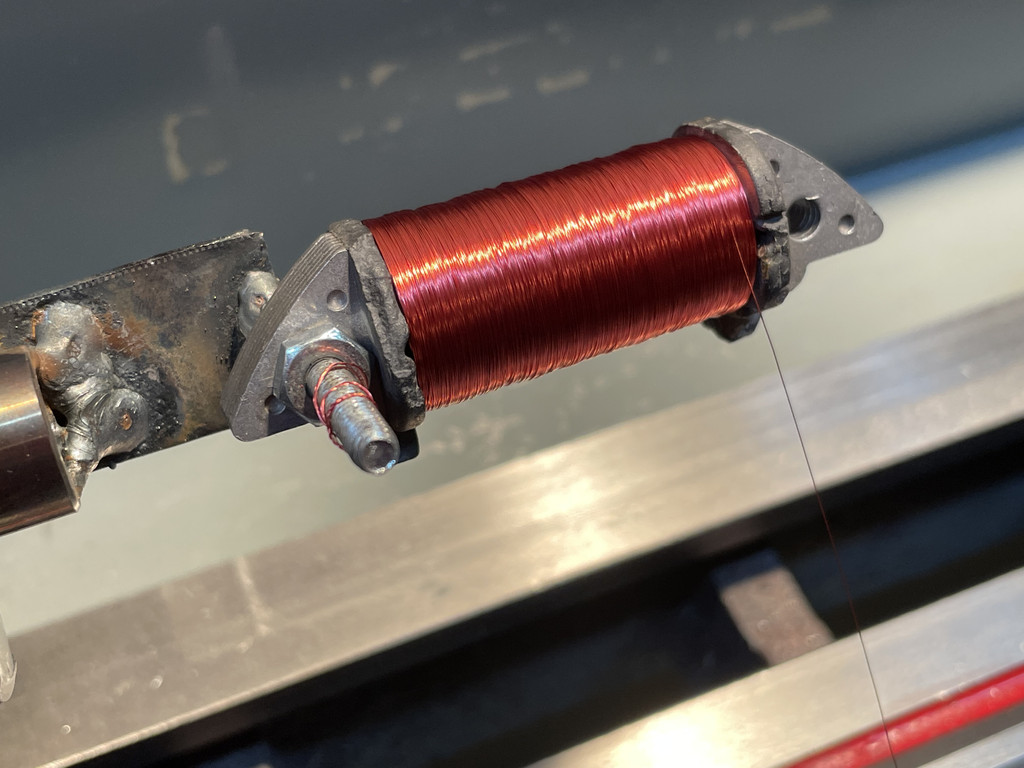

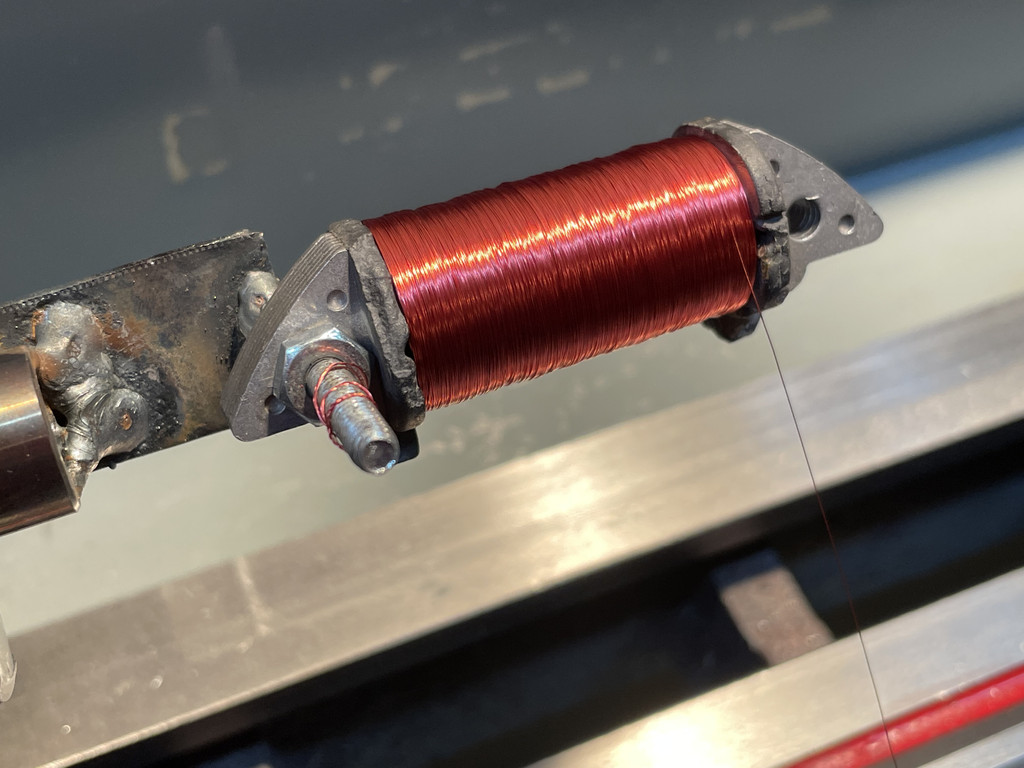

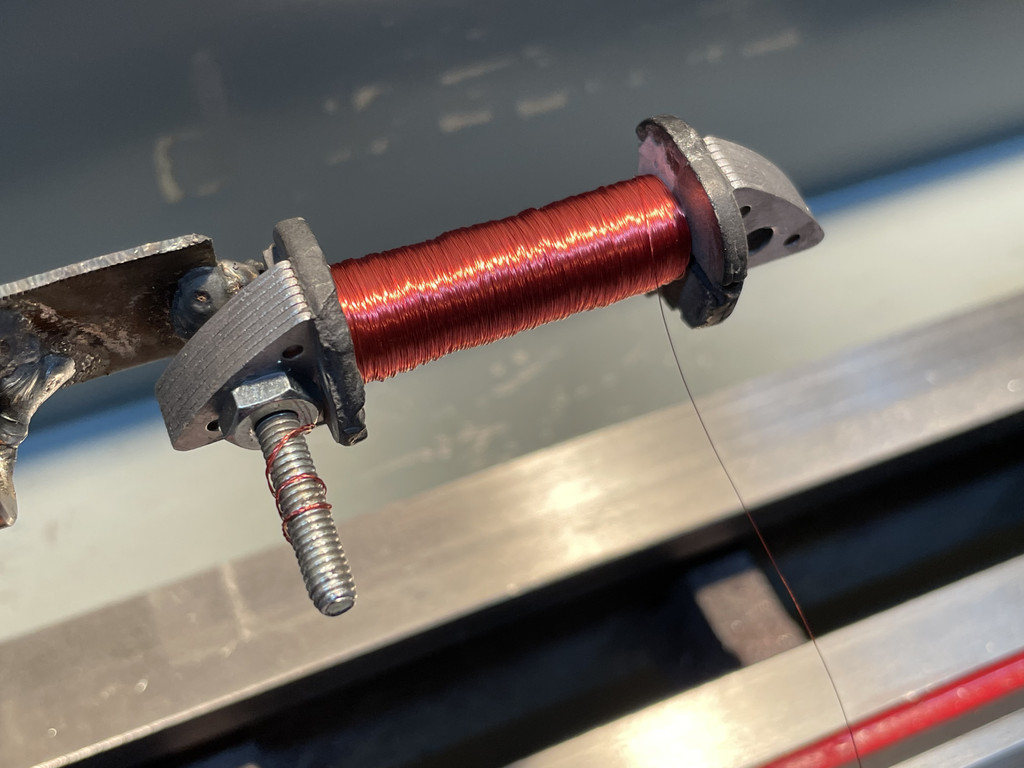

I used 36 gauge magnet wire. Because this is a single phase, AC stator, winding direction does not matter.

***Yes it does on the KDX specifically! See page 2!***

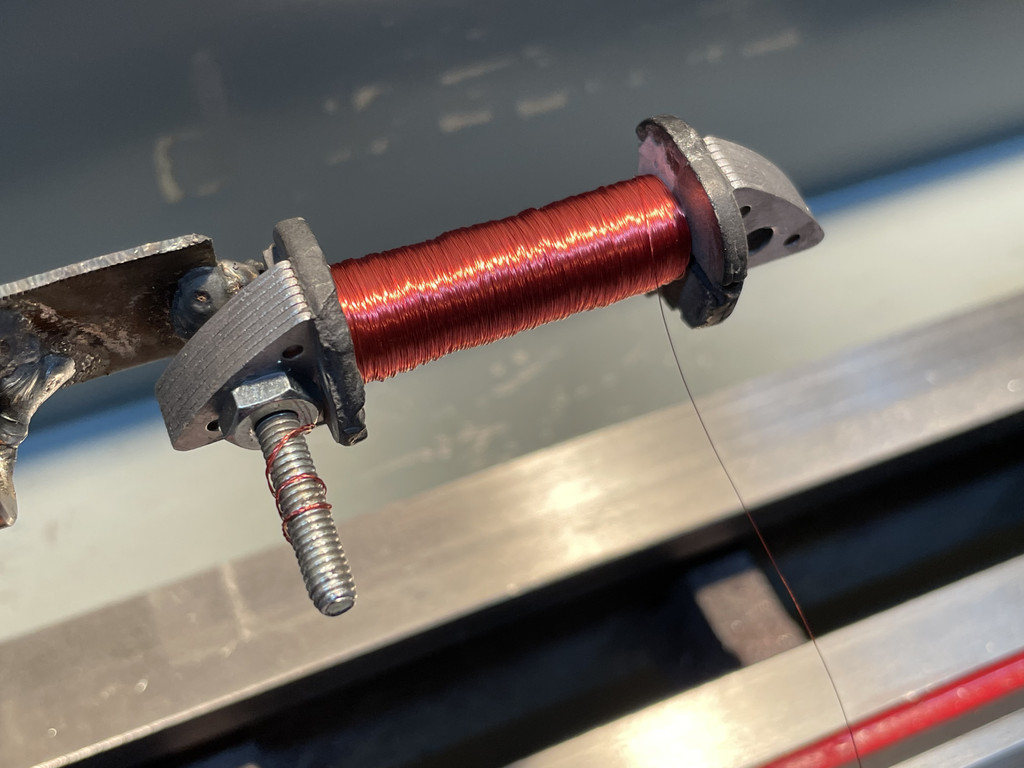

I lost count of the wraps, but this was maybe 100-150 layers. Getting there!

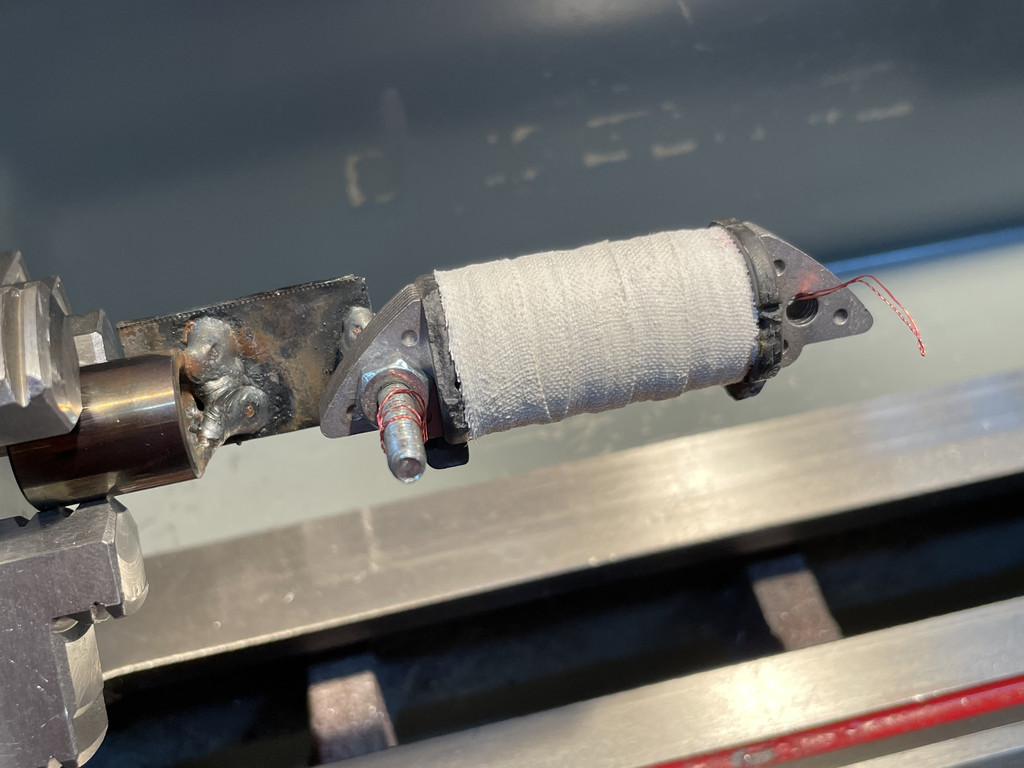

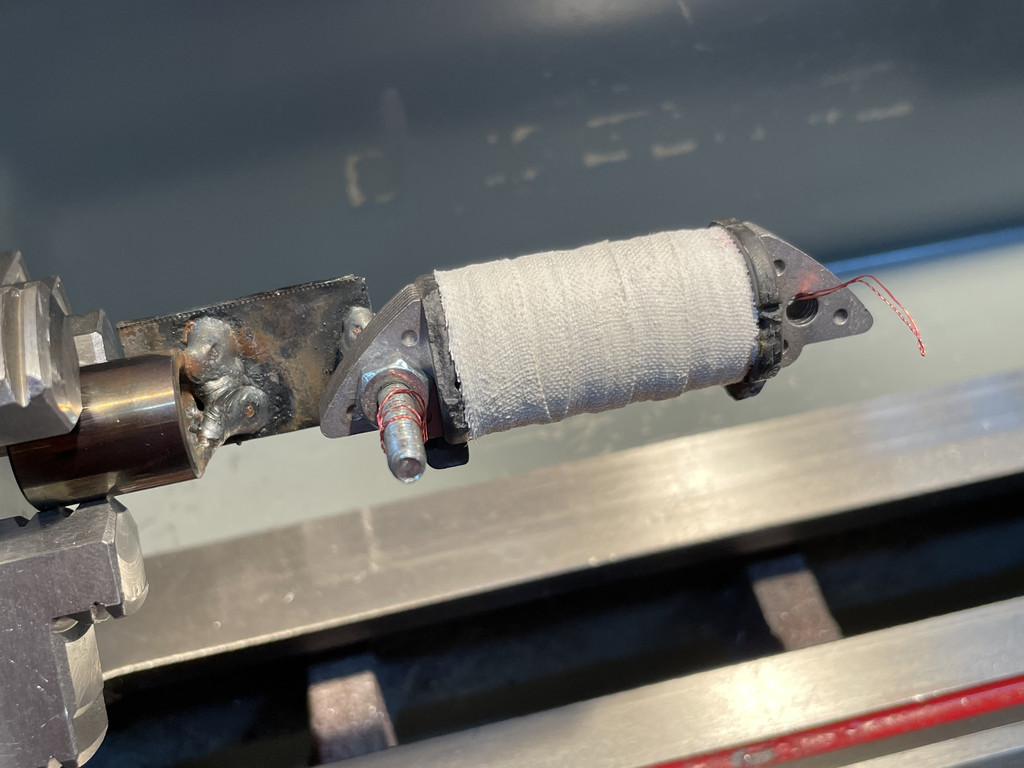

All finished! I tried to stay within the same dimensions as factory. Getting this far took me about 90 minutes. Twice, I had the wire break on me, and had to completely unwind and restart. This wire is about as thick as a human hair, you need just enough tension to keep it taught, but not so much that you snap it. It's impossible to count, but if I had to guess I'd say this was anywhere from 300-400 wraps of wire. Used about half of a 1/4 lb spool. Once the winding was finished, both ends were quadrupled up and twisted for strength, and some cloth tape was used to secure everything for now.