Page 1 of 2

KLX300 fork rod

Posted: 07:32 pm Jul 12 2024

by H Muz

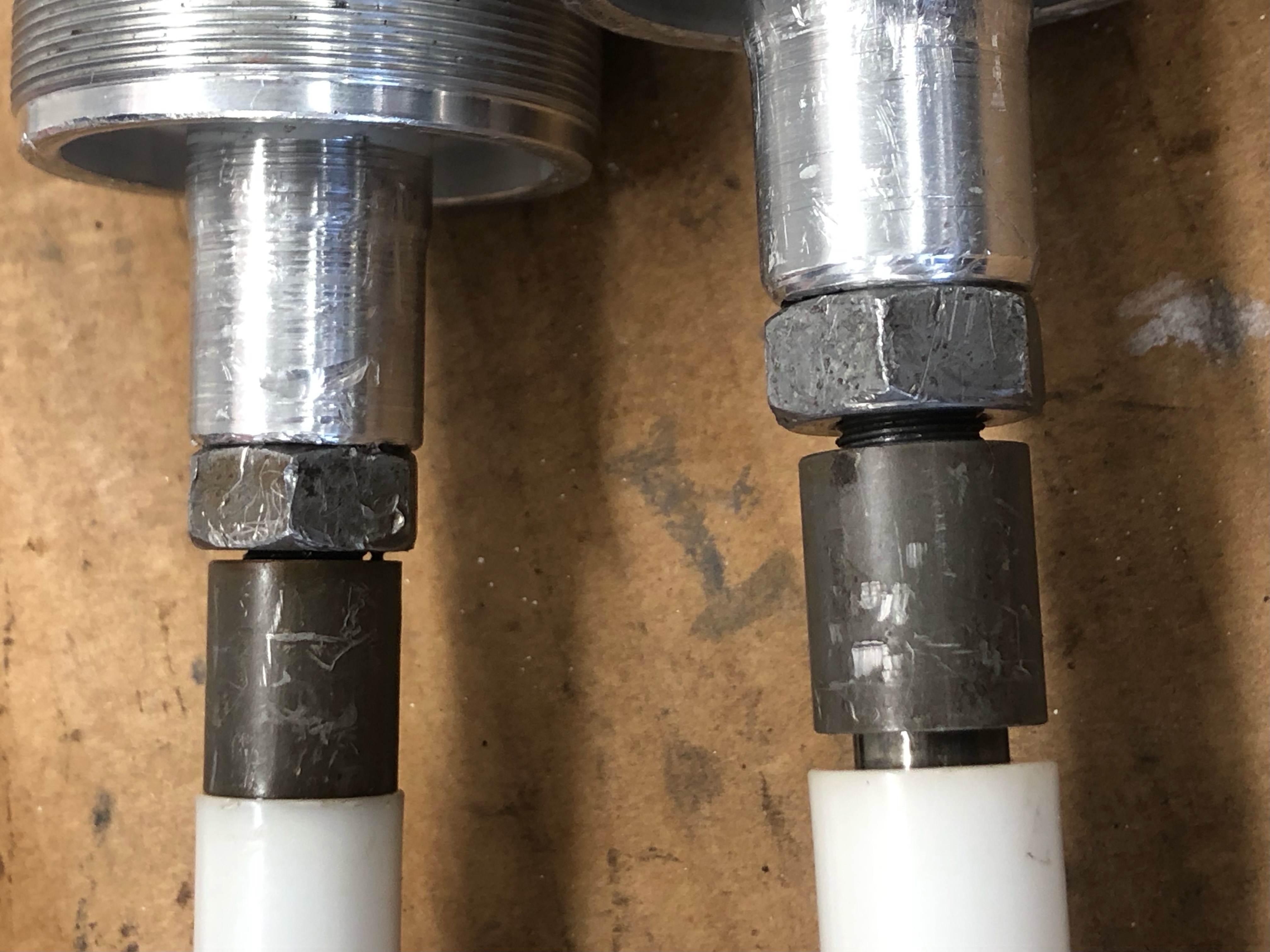

While removing seals, I noticed different lengths of the threaded end, one side is 18.5mm the other is 22.5mm, does this matter or inconsequential?

- IMG_5975.jpeg (1.92 MiB) Viewed 15208 times

Re: KLX300 fork rod

Posted: 09:34 am Jul 13 2024

by Slick_Nick

Aren't there supposed to be O-Rings in there against the plastic guides? Been awhile since I was into a set of KLX forks, I know the KX stye use them.

Re: KLX300 fork rod

Posted: 10:21 am Jul 13 2024

by H Muz

Re: KLX300 fork rod

Posted: 12:34 pm Jul 13 2024

by bufftester

The KX forks use an o-ring there, but the KLX ones don't. As far as I remember, the top of that shaft is where the cap screws on to retain the spring, not sure why they would be different lengths.

Re: KLX300 fork rod

Posted: 06:00 pm Jul 13 2024

by KDXGarage

Do the caps thread all the way down and bottom out?

Re: KLX300 fork rod

Posted: 02:27 am Jul 14 2024

by H Muz

Yep the caps bottom out before making contact with the rod nut, which can't be good. Obviously, I'll have to sort that out

Re: KLX300 fork rod

Posted: 12:44 pm Jul 14 2024

by bufftester

The piston rod nut is the lock nut for the fork cap, You screw the fork cap on then use the lock nut to hold it all in place.

Re: KLX300 fork rod

Posted: 02:22 pm Jul 14 2024

by KDXGarage

Yes, spin the caps all the way down to a certain torque, then torque the nut / cap.

Re: KLX300 fork rod

Posted: 12:43 am Jul 15 2024

by H Muz

Yep thanks guys

Re: KLX300 fork rod

Posted: 12:02 am Aug 14 2024

by H Muz

Hey guys just to confirm: The alloy fork caps should NOT bottom out on the fork rod when wound on, correct? Picture below shows fork caps bottomed out, and not securing against steel nuts. (Also shows that the threaded section is longer on one than the other.)

- Fork1.jpeg (1.91 MiB) Viewed 14549 times

Re: KLX300 fork rod

Posted: 02:35 am Aug 14 2024

by KDXGarage

I just looked it up in the service manual. It doesn't say there is a torque value on tightening the cap. It is 11 foot-pounds for the nut against the cap. I would just wind the cap down snug, then tighten the nut against it.

You will need a fork spring holding tool or a helper to do this.

https://item-shopping.c.yimg.jp/i/n/hirochi_57001-1286

57001-1286 is the Kawasaki part number. You can make a homemade tool. I have the OEM tool and have used it on a friend's KLX300R forks he put on his 1197 KDX200, as well as other KDX / KX forks. It works great.

Re: KLX300 fork rod

Posted: 02:47 am Aug 14 2024

by H Muz

If that applies to KLX300 forks, then there is too much threaded rod shown above. I can't back off the nut as that would then loosen the steel collar\spacer that's against the white plastic spring guide holding it all firm.

So how does one reduce the amount of thread protruding beyond the nut? So I can get the cap to screw down against the nut? Is there some other adjustment at the other end of the rod, at the valve end perhaps?

The fact that the top photo shows different lengths of thread makes me think that a previous owner has messed with it somehow...

Re: KLX300 fork rod

Posted: 02:55 am Aug 14 2024

by KDXGarage

Chamfered end goes up on the nut, by the way.

Someone has scratched the hell out of it.

The nut is not supposed to hold that spacer and guide firm. Any damage inside the fork cap threads?

EDIT: What is the length of threading on the top of each rod after removing the nut and spring guide?

Re: KLX300 fork rod

Posted: 03:04 am Aug 14 2024

by H Muz

Nope, fork cap threads are good. Yeh someone has had a good chew on it for sure.

When you say the "chamfered end goes up on the nut" you mean the nut winds up against the fork cap like this pic?

- Fork2.jpeg (1.32 MiB) Viewed 14531 times

Re: KLX300 fork rod

Posted: 03:46 am Aug 14 2024

by KDXGarage

Yes, the nut goes against the bottom of the cap. The manual states there is a chamfered side on one of the sides of the nut.

"Screw the rod nut [A] onto the push rod with the chamfered side up."

Re: KLX300 fork rod

Posted: 03:57 am Aug 14 2024

by H Muz

Ok roger that cheers. But in my situation, if I did that, as shown in the photo above, it would leave that metal collar\spacer fee to slide up & down on the rod, surely that can't be by design?

I also have a screen-grab of 06/07 KLX250 forks from youtube which shows no clearances, which is what I think it should look like, yeh?

- 2006_klx250s_Fork.jpeg (144.25 KiB) Viewed 14524 times

Re: KLX300 fork rod

Posted: 05:00 am Aug 14 2024

by KDXGarage

EDIT: copy and pasted my first post to just merge it with this second post.

There has to be a touch of room or the nut would not have room to tighten up against the fork cap.

When you take the cap, nut and spring guide off, is the threaded portion the same length on both?

I know the spring guide is made of plastic. The collar is steel, correct?

Here's a picture of what 1994 USA KDX200 forks look like, which is pretty similar to KLX. Sorry for lack of detail, but I took the picture in 2005.

- 1994KDX200Forks.jpg (56.58 KiB) Viewed 14517 times

Re: KLX300 fork rod

Posted: 05:12 am Aug 14 2024

by H Muz

Just hold the nut and tighten the cap down on to it? (Without the cap bottoming out on the rod)

Yep, the collar is steel. I'll check the rod thread length tomorrow sometime, thanks for your help.

Re: KLX300 fork rod

Posted: 05:27 am Aug 14 2024

by KDXGarage

Be sure to pump the rod several times during oil filling to bleed air from the cartridge. You can get a really large wrench and hold the spring down so you can tighten the nut up against the cap. 15 Newton-meters

Maybe some operator cut more threads than they should have? Who knows.

You're welcome. I used to work on KDX suspension for forum members some back in 2005. I still remember most of it. :-)

Re: KLX300 fork rod

Posted: 12:08 am Aug 15 2024

by H Muz

Right, all sorted man. As you suggested, I checked thread length which is fine. What had happened was alloy bush\stopper thingy that the plastic spring guide sits on had come away from the retainer\circlip, which explains why I had additional thread at the top end.

So I tapped the bush back over the circlip and peened down the "flared" end over the circlip (you can see some fracturing), so it wouldn't pop back out again. Hopefully that should do the trick.

Maybe that steel nut was wound down too tight on the top end of the spring guide, causing excessive pressure on the bush, therefore the bush eventually came away from the circlip, who knows...

Anyway all bushes and seals now replaced, will throw oil in tomorrow.

- 1.jpg (546.13 KiB) Viewed 14446 times

- 2.jpg (281.5 KiB) Viewed 14446 times

- 3.jpg (386.53 KiB) Viewed 14446 times