Page 1 of 1

KIPS Resonator spacer.

Posted: 07:04 am Jul 17 2015

by Tioli

Hi

I'm after comparison and confirmation.

I made a 17mm spacer say 3/4 inch and it has a really nice effect on my motor. Problem is I made changed to mine that sent me on a different path to the norm. The split in the path was wrapping the exhaust.

I'm after some one with curiosity, the ability to fabricate or get it done, has the RB head carb, descent air box, VFORCE 3 reeds, cleaned the ports up, fully advanced ignition, desert pipe with straight through exhaust. Or close to it.

Putting in a spacer can't hurt your motor and could change it.

Big honking spacer three times conventional wisdom.

My results

http://www.trials.com.au/forum/viewtopi ... 387#p36387

Re: KIPS Resinator spacer.

Posted: 07:12 am Jul 18 2015

by C George

How did you happen to pick that thickness ?

Is yours a 200 or 220 ?

Are you looking for someone to machine some ? I don't completely follow your question.

KIPS Resinator spacer.

Posted: 09:38 am Jul 18 2015

by Tioli

I picked that thickness because one of my tuning methods is to over shoot the mark then come back forth til you narrow it down to what works. In this case from what I can tell the ones sold are 6mm so three times that is 18 which should be a fair over shoot. I had 5 and 10mm plate plus an additional two gaskets is close enough. There is no for knowledge in that size just experimentation. Turns out it gave my set up a surprising result that I suspect will suit similar developed motors with a desert pipe.

I am presuming the list of what I have done to my motor is normal? After all I got most of it hear

Can't see it doing to much for a woods, standard pipe or 220. But then what do I know?

Mine is a 200 for now as I'm working on a second 200 barrel and boring it out to a 220 so I will be moving on and leave the norm behind.

Yes I'm presuming if anyone is curious enough to try a large spacer they could problem find a way to make there own spacer. Took me a few hours and working with metal is not my game.

It worked for me and it would be nice if it could be duplicated for similar setups and added to the standard list of mods. As said before what I did to mine apart from the exhaust wrap is standard stuff and not new it all comes from hear. Well maybe not the port and piston work. The piston work is just a personal thing and how could I live with myself if I overlooked all those casting irregularities. Easy path to duplicate and nothing individually special.

Re: KIPS Resinator spacer.

Posted: 03:21 pm Jul 18 2015

by C George

Not to sway this thread , but if you build a modded 220 you'll say " why did I wait so long ".

My son's 200 , now a 220 is a TOTALLY different animal. I Love riding it !

Dad works on it so Dad rides it when son is off to college. :) :)

It's FUN to experiment , just as long as you expect the worst.

KIPS Resinator spacer.

Posted: 08:15 pm Jul 18 2015

by Tioli

I have always enjoyed the development work as it brings a second element to riding.

As for disappointment Iv had a few. Every time I make a change I'm thinking how can I reverse this if needed.

An example is the exhaust wrap, it did the job of quietening But changed the nature of the pipe. Not unexpected and reversible with the exhaust spacer. Having said that it bought the tuned length back down and slightly lower but not the same.

This is why I would like to see what effect a large Resonator spacer has on a similar motor. I'm not taking the wrap off so can't do it myself.

I'm predicting it's really suited to a desert pipe. Now is that a standard motor and desert pipe or a enhanced motor and desert pipe?

I suspect this thread will peter out soon enough. For good reason most people are conservative when it comes to experimenting.

I can only say there is no way adding a large Resonator spacer for a desert pipe can hurt your motor. A desert pipe by its very design is not efficient in the lower rev range. That's the reason for having a Resonator. All I have done is make it a 200 cc Resonator not a 125 one. It's supposed to slow the exiting puls all I have done is slow it more which will make it repack better and give a bigger bang. Rrepacking more of your charge and not wasting it in the low range. It won't hurt, That's what a woods pipe does.

Re: KIPS Resinator spacer.

Posted: 10:07 am Jul 19 2015

by Julien D

C George wrote:Not to sway this thread , but if you build a modded 220 you'll say " why did I wait so long ".

My son's 200 , now a 220 is a TOTALLY different animal. I Love riding it !

Dad works on it so Dad rides it when son is off to college. :) :)

It's FUN to experiment , just as long as you expect the worst.

It's all personal, IMO. I prefer my 200 to any 220 I've ridden. But then again, I also prefer my E series 200 engine to any H series 200 I've ridden. The power curve is just perfect for my needs.

Tioli,

What piston are you planning to use with the overbore? I am fairly certain a stock 220 piston won't work. You'd need a 220 head and jug for that.

Re: KIPS Resinator spacer.

Posted: 01:39 am Jul 20 2015

by Actionman

I bought 1/8 black plexiglass and cut out six kips chamber templates for my 2000 kx250. I could feel a noticible difference to the way my engine would pick up from the bottom end. My kx had zero bottom end (it has a pro circuit pipe from when i bought the bike disassembled in boxes). I have six spacers on it now but plan to try eight to see if a full inch helps power any. I dont know how robust plexiglass is to heat, but ive ridden for 1 1/2 hour stretches and the havent melted.

Re: KIPS Resinator spacer.

Posted: 01:44 am Jul 20 2015

by Actionman

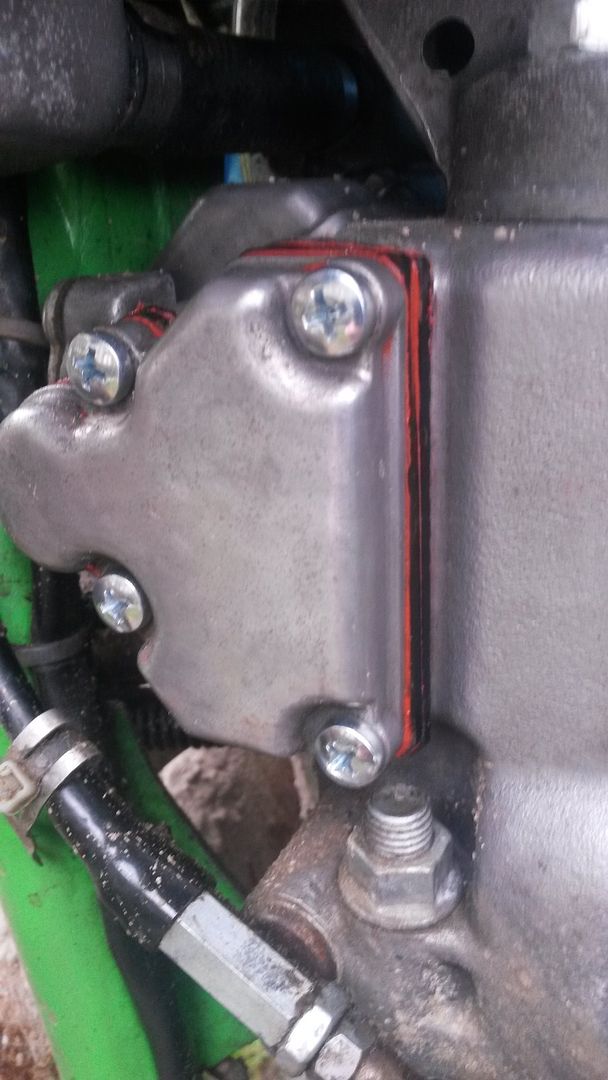

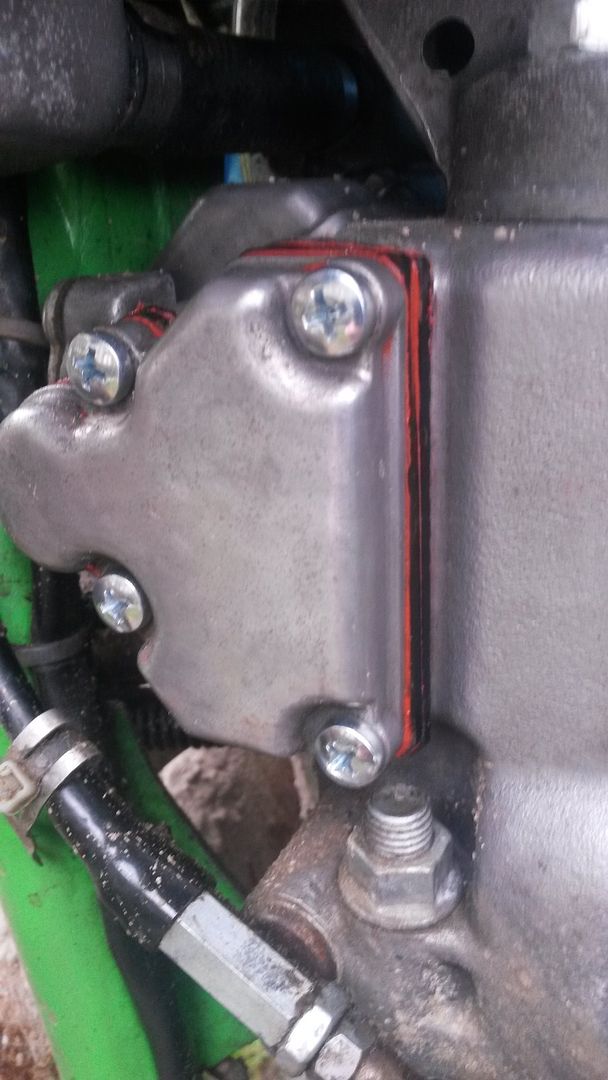

Heres what i did with the plexiglass. This was when i started with 1/4 inch (two 1/8 templates).

KIPS Resinator spacer.

Posted: 02:43 am Jul 20 2015

by Tioli

Wow Actionman your a brave man for using plexiglass there. I used to have sensor in the begining of expansion chambers to monitor exhaust gas temperatures so I wouldn't melt pistons. Your a lot closer than that

Yeah I would give a big one a go, to a degree though I would have thought they would have designed a 250 one for a 250. Not a 125 for a 200 like ours. Then again if you have changed the pipe you may just be resizing for your chamber.

Julian D, now you have done it. That little seed of doubt is planted. Strangely enough I sent a 220 head of to RB to get touched up and that should be making its way back now. The 200 barrel was sent to the platers last week to be boared and a 220 Wossner piston straight to them so I have never compared.

Is this one of those "expect the worst" situations C George was talking about

Re: KIPS Resinator spacer.

Posted: 05:17 am Jul 20 2015

by C George

Julien D wrote:C George wrote:Not to sway this thread , but if you build a modded 220 you'll say " why did I wait so long ".

My son's 200 , now a 220 is a TOTALLY different animal. I Love riding it !

Dad works on it so Dad rides it when son is off to college. :) :)

It's FUN to experiment , just as long as you expect the worst.

It's all personal, IMO. I prefer my 200 to any 220 I've ridden. But then again, I also prefer my E series 200 engine to any H series 200 I've ridden. The power curve is just perfect for my needs.

Tioli,

What piston are you planning to use with the overbore? I am fairly certain a stock 220 piston won't work. You'd need a 220 head and jug for that.

+ 1 on agreeing about the personal preference.

The 200 cylinder must be able to take up 70mm as that is what the 225 kit is . DON'T quote me on this as it sounds darn thin to think about punching it out 4mm.

I'd maybe play it safer and only go to the 220 stock bore of 69mm.

Yes , a PC 2 or Desert pipe is a MUST for this size engine.

Re: KIPS Resinator spacer.

Posted: 04:43 am Jul 21 2015

by Actionman

Just a note: I took my kips chamber off to check the plexiglass spacer, and the one closest to the cylinder was brittle and broken from heat. If anybody else tries it id recommend making a heat shield/gasket out of aluminum foil to put between the cylinder and the first spacer. Might use high heat silicon as well. The other spacers were fine.

KIPS Resinator spacer.

Posted: 07:39 am Jul 21 2015

by Tioli

I don't think plexiglass is a good material to use? I'm rough with converting to F and remembering these temps but I think plexiglass goes soft around 300' and exhaust temps are around 1800.

KIPS Resinator spacer.

Posted: 08:47 am Jul 21 2015

by Tedh98

Tioli wrote:I don't think plexiglass is a good material to use?

Totally agree on that. Plexiglass might be good for testing different thicknesses, but I wouldn't trust it long term.

Aside from the heat, I doubt that plexiglass is going to stand up well to oil.

KIPS Resinator spacer.

Posted: 11:21 am Jul 22 2015

by pumpguy

Typically, sheet plastics like Plexiglas Acrylic and Lexan Polycarbonate are not recommended for use beyond 170 -285 degrees F., depending on the actual material used.

I would try 1/8" thick aluminum. This is easy to cut and holds up to heat and petroleum. A sandwich of 1/8" thickness spacers can be used to increase the resonator volume to whatever works best for you.

Re: KIPS Resinator spacer.

Posted: 07:47 pm Jul 22 2015

by Actionman

Yeah, plexiglass was just to see if i could feel a difference. Unfortunately i have no machining capacity to make one out of aluminum. Guess ill run without one.

KIPS Resonator spacer.

Posted: 03:08 am Jul 23 2015

by Tioli

Last time I made something out of plexiglass I used a hacksaw, files and drill. Aluminium is soft and can be worked with woodworking tools just like plexiglass

I usually go to metal shops and get scraps for my projects.