That is one of those things where you later think, Oh, I should have done that.

1993 KDX 250 Questions...

- KDXGarage

- KDXRider.net

- Posts: 14652

- Joined: 06:45 am Nov 01 2004

- Country: United States of America

- Location: AL, USA

- Has thanked: 4 times

- Been thanked: 8 times

- Contact:

Re: 1993 KDX 250 Questions...

pretty cool on keeping the nuts in order

That is one of those things where you later think, Oh, I should have done that.

That is one of those things where you later think, Oh, I should have done that.

Thank you for participating on kdxrider.net.

To post pictures from a device: viewtopic.php?f=88&t=24128

To post pictures from a device: viewtopic.php?f=88&t=24128

-

Rangerman

- Member

- Posts: 23

- Joined: 08:59 pm Feb 25 2018

- Country: United States

Re: 1993 KDX 250 Questions...

Thanks.Jason wrote:pretty cool on keeping the nuts in order

That is one of those things where you later think, Oh, I should have done that.

Now what I have yet to determine is how to disconnect the power valve.

On my KTM's it is really straight forward but with the KIPs it is obviously different and I am unfamiliar with its setup/design.

I do have a factory (OEM) manual that I will be referencing so that should come in handy.

Rangerman

CLW87

"We go way back, you and me"

"We go way back, you and me"

-

Rangerman

- Member

- Posts: 23

- Joined: 08:59 pm Feb 25 2018

- Country: United States

1993 KDX 250 Questions...

Well after a brief hiatus I have an opportunity to get back on task with the '93 KDX 250.

I did get to enjoy a woods ride aboard my vintage '92 KTM 300EXC recently and I must say it is still a fine woods machine even though it is well into its golden years.

I am looking forward to being able to conduct a sort of "shootout" between the two to see how each one does compared to the other?

Should prove to be an interesting test of two venerable enduro bikes of yesteryear.

https://vimeo.com/275356238

Back to things pertaining to the KDX...

I removed the engine brace bracket from frame.

I was able to remove the head relatively easy.

Lots of carbon build up to clean off.

Piston carbon coated as well.

Gasket came off clean.

Removing power valve cover.

Disconnecting the linkage nut.

Linkage arm disconnected.

Breaking cylinder nuts a few increments at a time in a crisscross pattern.

I had to use a open end wrench on the two front since it was not possible to fit a socket onto them.

Makes me question how I will be able to torque these two back to specs with re install?

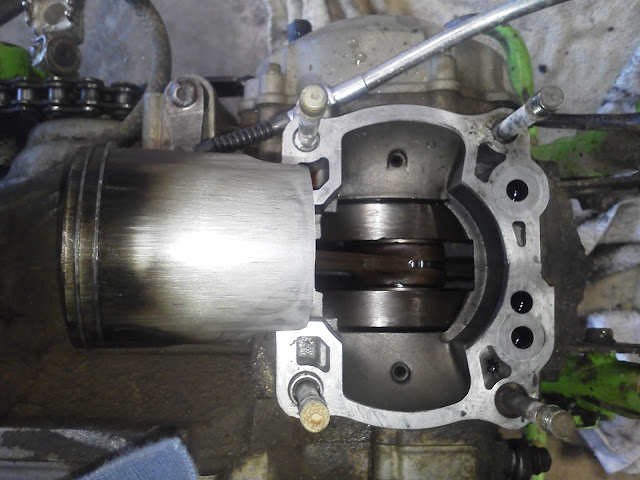

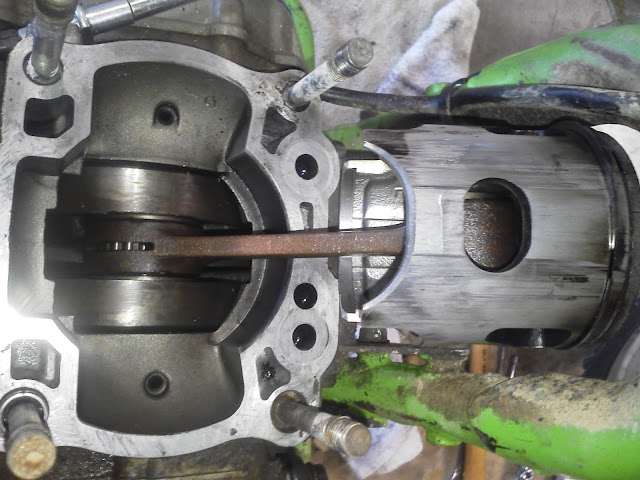

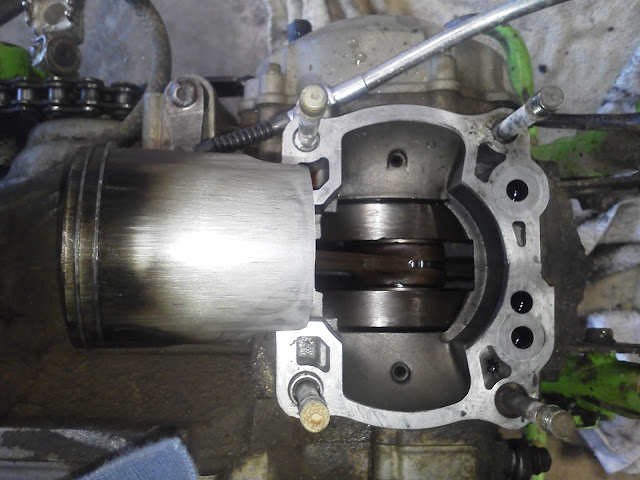

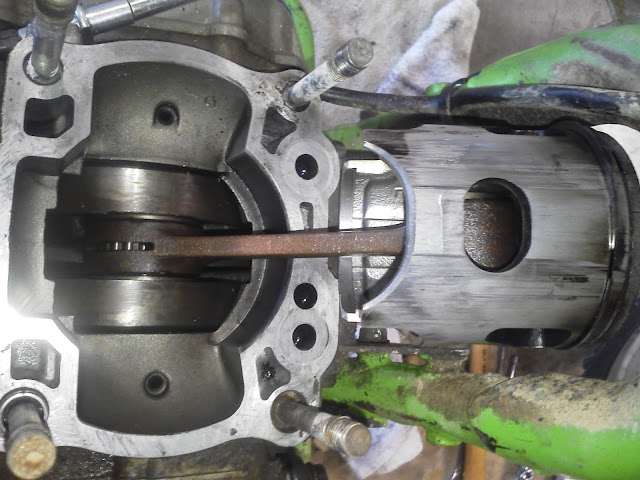

Lifting the cylinder (jug) off very carefully.

Cylinder off successfully.

Removing the snap ring from one side of the piston.

Pushing the crank pin out from one side of the piston after snap ring is removed.

Removing the needle bearing.

Cylinder head and piston ready for inspection.

To be continued...

Rangerman

I did get to enjoy a woods ride aboard my vintage '92 KTM 300EXC recently and I must say it is still a fine woods machine even though it is well into its golden years.

I am looking forward to being able to conduct a sort of "shootout" between the two to see how each one does compared to the other?

Should prove to be an interesting test of two venerable enduro bikes of yesteryear.

https://vimeo.com/275356238

Back to things pertaining to the KDX...

I removed the engine brace bracket from frame.

I was able to remove the head relatively easy.

Lots of carbon build up to clean off.

Piston carbon coated as well.

Gasket came off clean.

Removing power valve cover.

Disconnecting the linkage nut.

Linkage arm disconnected.

Breaking cylinder nuts a few increments at a time in a crisscross pattern.

I had to use a open end wrench on the two front since it was not possible to fit a socket onto them.

Makes me question how I will be able to torque these two back to specs with re install?

Lifting the cylinder (jug) off very carefully.

Cylinder off successfully.

Removing the snap ring from one side of the piston.

Pushing the crank pin out from one side of the piston after snap ring is removed.

Removing the needle bearing.

Cylinder head and piston ready for inspection.

To be continued...

Rangerman

CLW87

"We go way back, you and me"

"We go way back, you and me"

- KDXGarage

- KDXRider.net

- Posts: 14652

- Joined: 06:45 am Nov 01 2004

- Country: United States of America

- Location: AL, USA

- Has thanked: 4 times

- Been thanked: 8 times

- Contact:

Re: 1993 KDX 250 Questions...

Heck yeah. Cool post.

Someone let that piston and rings run for too long.

https://www.motionpro.com/product/08-0134

Motion Pro Torque Wrench adapter for the cylinder nuts.

Did you not have a box end (closed) wrench for the nut removal?

Someone let that piston and rings run for too long.

https://www.motionpro.com/product/08-0134

Motion Pro Torque Wrench adapter for the cylinder nuts.

Did you not have a box end (closed) wrench for the nut removal?

Thank you for participating on kdxrider.net.

To post pictures from a device: viewtopic.php?f=88&t=24128

To post pictures from a device: viewtopic.php?f=88&t=24128

-

Rangerman

- Member

- Posts: 23

- Joined: 08:59 pm Feb 25 2018

- Country: United States

Re: 1993 KDX 250 Questions...

Jason wrote:Heck yeah. Cool post.

Someone let that piston and rings run for too long.

https://www.motionpro.com/product/08-0134

Motion Pro Torque Wrench adapter for the cylinder nuts.

Did you not have a box end (closed) wrench for the nut removal?

Thanks for the link for the adapter Jason, I was not aware of this nifty type of tool.

I will get one for the reinstall.

As far as the condition of the piston that you mentioned, I had my suspicion that this KDX was run hard. Not abused per se but nevertheless used harshly when compared to both my EXC and DXC KTM's.

Still I have a hunch that it has some more to offer in the way of woods riding, especially the type of riding that I do... The slow but sure kind.

Here is the head ready for Easy Off and Scotch-Brite...

Coated liberally and to sit for a bit while it loosens the carbon buildup.

Well what it revealed was not good...

But again not a complete surprise considering my suspicions.

According to this information the damage (pitting) from debris in the engine and/or slight

detonation is somewhere between moderate to extensive.

I would suggest extensive.

http://www.millennium-tech.net/pdf/2_st ... needed.pdf

I may check to see if I can source a used (e-bay) replacement head and for how much compared to sending this out to be serviced.

Then go from there.

I have kept in the back of my mind all along with this KDX experience the possibility of when to give up the ship.

I will not invest a substantial amount of funds to bring this machine back to standards.

There has to be a cut off, especially when similar machines are plentiful and perhaps in better overall condition.

I have no desire to restore this to be a museum piece, all I am interested in accomplishing is the potential of using it as a play bike in the woods.

Nothing pretty just practical.

To be continued...

Rangerman

CLW87

"We go way back, you and me"

"We go way back, you and me"

- SS109

- KDXRider.net

- Posts: 6117

- Joined: 05:11 am Aug 23 2009

- Country: USA

- Location: Tucson, AZ, USA

- Has thanked: 4 times

- Been thanked: 9 times

- Contact:

1993 KDX 250 Questions...

That damage is definitely from something metal bouncing around in there at one time. I think Millennium can machine the chamber to smooth it out and then machine the whole head down to keep compression stock. However, a good used head will be cheaper.

Youtube Channel: WildAzzRacing

AZ State Parks & Trails OHV Ambassador - Trail Riders of Southern AZ

Current KDX: '98 KDX220

Old KDX: '90 KDX200 -White/Blue

'11 GasGas EC250R

AZ State Parks & Trails OHV Ambassador - Trail Riders of Southern AZ

Current KDX: '98 KDX220

Old KDX: '90 KDX200 -White/Blue

'11 GasGas EC250R

- KDXGarage

- KDXRider.net

- Posts: 14652

- Joined: 06:45 am Nov 01 2004

- Country: United States of America

- Location: AL, USA

- Has thanked: 4 times

- Been thanked: 8 times

- Contact:

Re: 1993 KDX 250 Questions...

OUCH!

Just keep shopping for a used one on eBay. They are not too rare.

Just keep shopping for a used one on eBay. They are not too rare.

Thank you for participating on kdxrider.net.

To post pictures from a device: viewtopic.php?f=88&t=24128

To post pictures from a device: viewtopic.php?f=88&t=24128

-

Rangerman

- Member

- Posts: 23

- Joined: 08:59 pm Feb 25 2018

- Country: United States

1993 KDX 250 Questions...

Thanks for the information.SS109 wrote:That damage is definitely from something metal bouncing around in there at one time. I think Millennium can machine the chamber to smooth it out and then machine the whole head down to keep compression stock. However, a good used head will be cheaper.

I have already sourced a decent used KDX250 head and you are right, there are plenty to choose from and they are at a lesser expense than machining this damaged one.

Rangerman

CLW87

"We go way back, you and me"

"We go way back, you and me"

-

Rangerman

- Member

- Posts: 23

- Joined: 08:59 pm Feb 25 2018

- Country: United States

Re: 1993 KDX 250 Questions...

Yes, I have already found a replacement KDX250 head.Jason wrote:OUCH!

Just keep shopping for a used one on eBay. They are not too rare.

Take a look at the piston after I cleaned it up.

I am trying to determine what replacement piston to go with.

The piston has the letter B stamped on the top and from some research that I have done recently I have understood that to mean that this may be the second piston (top end) since new. If new production pistons are labeled with the letter A then that would make sense and piston C would be the next in line after B.

I understand that Wiseco has a one size fits all (67.4mm) where as Pro X offers sizes to match the closest (present) size, albeit in exceptionally small increments (mm's).

I do not have access to a bore gauge to determine bore size.

This is an interesting video about two stroke cylinder inspection from Slavens.

He suggests a bore gauge is not a good choice for a two stroke cylinder (@4:36 min into video) since it has so many ports, you can only measure from the exhaust port up which in turn does not provide enough information.

It would probably be safe to go one size up (C) anyway since the increments are minute (small) rather than the same size (B) that is installed presently since it is obvious that it has seen some very hard use which in turn would equate to the bore diameter of the cylinder suffering some enlargement (wear) as a result.

Rangerman

Last edited by Rangerman on 08:48 pm Jul 02 2018, edited 1 time in total.

CLW87

"We go way back, you and me"

"We go way back, you and me"

-

Rangerman

- Member

- Posts: 23

- Joined: 08:59 pm Feb 25 2018

- Country: United States

1993 KDX 250 Questions...

This is a video from the autumn of 2017 when I first acquired the '93 KDX250 (sans silencer).

I wanted to satisfy curiosity as to if it would fire up which it did even with low compression and that with relative ease.

As a result I knew that there was still some life left in this ol' vintage machine and perhaps well worth my time and effort in getting it sorted out and back into shape for some potential woods riding.

https://vimeo.com/278078325

Getting closer to that goal as I investigatre further what this needy machine really is in need of...

Rangerman

I wanted to satisfy curiosity as to if it would fire up which it did even with low compression and that with relative ease.

As a result I knew that there was still some life left in this ol' vintage machine and perhaps well worth my time and effort in getting it sorted out and back into shape for some potential woods riding.

https://vimeo.com/278078325

Getting closer to that goal as I investigatre further what this needy machine really is in need of...

Rangerman

CLW87

"We go way back, you and me"

"We go way back, you and me"

- KDXGarage

- KDXRider.net

- Posts: 14652

- Joined: 06:45 am Nov 01 2004

- Country: United States of America

- Location: AL, USA

- Has thanked: 4 times

- Been thanked: 8 times

- Contact:

Re: 1993 KDX 250 Questions...

1. Be careful in how long you let caustic set on aluminum.

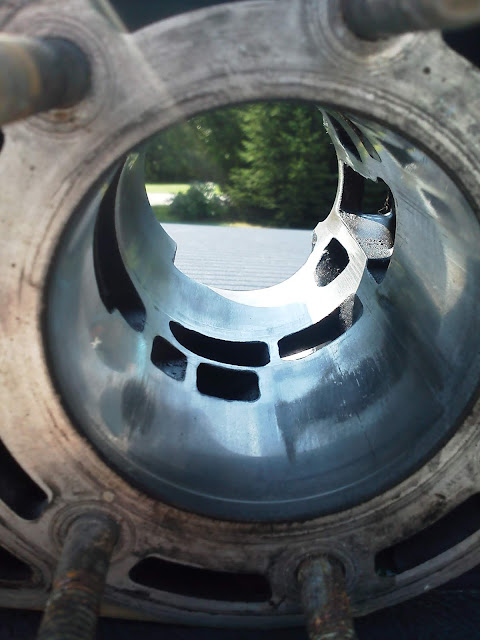

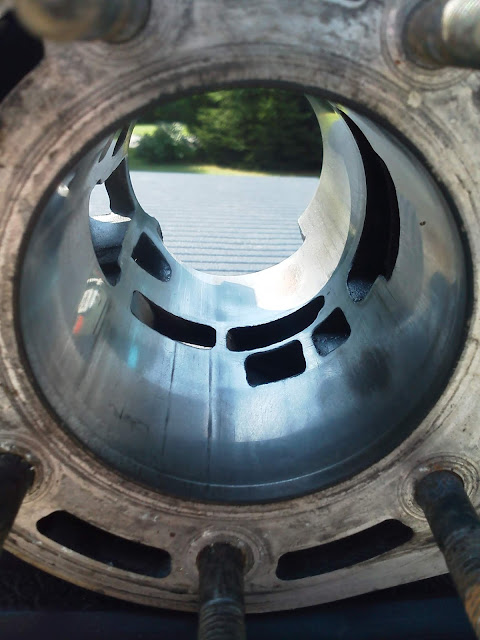

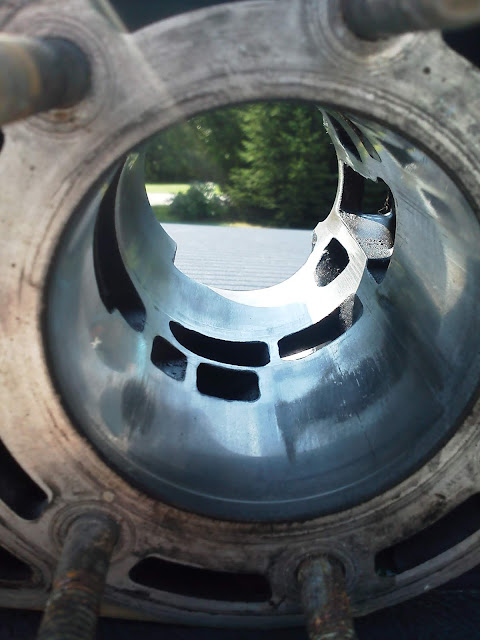

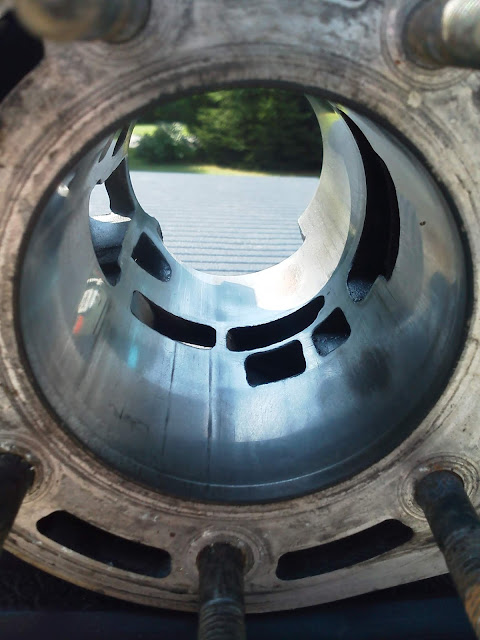

2. What does the cylinder look like? Having metal bounce around inside the engine at some point is not good.

3. Whichever (Mr. Goodwrench) previous owner kept running it after metal was bouncing around inside, did so for a while. There is a LOT of carbon built up.

2. What does the cylinder look like? Having metal bounce around inside the engine at some point is not good.

3. Whichever (Mr. Goodwrench) previous owner kept running it after metal was bouncing around inside, did so for a while. There is a LOT of carbon built up.

Thank you for participating on kdxrider.net.

To post pictures from a device: viewtopic.php?f=88&t=24128

To post pictures from a device: viewtopic.php?f=88&t=24128

-

Rangerman

- Member

- Posts: 23

- Joined: 08:59 pm Feb 25 2018

- Country: United States

1993 KDX 250 Questions...

KDX 250 cylinder bore...

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

#11

#12

#13

#14

I will measure bore diameter later today.

Rangerman

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

#11

#12

#13

#14

I will measure bore diameter later today.

Rangerman

CLW87

"We go way back, you and me"

"We go way back, you and me"

- SS109

- KDXRider.net

- Posts: 6117

- Joined: 05:11 am Aug 23 2009

- Country: USA

- Location: Tucson, AZ, USA

- Has thanked: 4 times

- Been thanked: 9 times

- Contact:

1993 KDX 250 Questions...

That cylinder looks to be in desperate need of replating.

Youtube Channel: WildAzzRacing

AZ State Parks & Trails OHV Ambassador - Trail Riders of Southern AZ

Current KDX: '98 KDX220

Old KDX: '90 KDX200 -White/Blue

'11 GasGas EC250R

AZ State Parks & Trails OHV Ambassador - Trail Riders of Southern AZ

Current KDX: '98 KDX220

Old KDX: '90 KDX200 -White/Blue

'11 GasGas EC250R

-

Rangerman

- Member

- Posts: 23

- Joined: 08:59 pm Feb 25 2018

- Country: United States

1993 KDX 250 Questions...

Cylinder...

Piston...

To be continued...

Rangerman

Piston...

To be continued...

Rangerman

CLW87

"We go way back, you and me"

"We go way back, you and me"

- KDXGarage

- KDXRider.net

- Posts: 14652

- Joined: 06:45 am Nov 01 2004

- Country: United States of America

- Location: AL, USA

- Has thanked: 4 times

- Been thanked: 8 times

- Contact:

Re: 1993 KDX 250 Questions...

ID's of cylinders are measured with bore gauges, not calipers.

says it measures to 0.001 mm

says it measures to 0.001 mm

Thank you for participating on kdxrider.net.

To post pictures from a device: viewtopic.php?f=88&t=24128

To post pictures from a device: viewtopic.php?f=88&t=24128

-

Rangerman

- Member

- Posts: 23

- Joined: 08:59 pm Feb 25 2018

- Country: United States

Re: 1993 KDX 250 Questions...

Yes, I thought so to, until I watched an excellent video by Jeff Slavens;Jason wrote:ID's of cylinders are measured with bore gauges, not calipers.

Where he suggests (@4:32 time mark) that a bore gauge is somewhat useless on a 2T cylinder since there are some many ports and henceforth can only be measured from the exhaust port up which really does not reveal enough to make using it worthwhile.

Interesting that he also states that because of these ports 2T cylinders after 20-40 hrs of use just become more untrue, warping easily.

I just wanted to get a basic point of reference using the calipers before committing to the Wiseco 67.4, which I am going to do.

This machine has seen some hard use, that is obvious and for what I am going to use it for cleaning up the cylinder and installing a Wiseco will be good enough to get me there.

I examined the top portion of the cylinder (lip) and the ridge is minimal which can be cleaned up a bit as well.

Exhaust port (finish) wear is minimal also and after it is tidied up will not prove to be an issue.

I do not plan to race this machine nor even ring it out occasionally, just some lazy woods riding at a enjoyable pace.

Rangerman

CLW87

"We go way back, you and me"

"We go way back, you and me"

- KDXGarage

- KDXRider.net

- Posts: 14652

- Joined: 06:45 am Nov 01 2004

- Country: United States of America

- Location: AL, USA

- Has thanked: 4 times

- Been thanked: 8 times

- Contact:

Re: 1993 KDX 250 Questions...

I think the manual says something about measuring it about 30 mm down from the top. I can not remember right off the top of my head.

Thank you for participating on kdxrider.net.

To post pictures from a device: viewtopic.php?f=88&t=24128

To post pictures from a device: viewtopic.php?f=88&t=24128

- SS109

- KDXRider.net

- Posts: 6117

- Joined: 05:11 am Aug 23 2009

- Country: USA

- Location: Tucson, AZ, USA

- Has thanked: 4 times

- Been thanked: 9 times

- Contact:

1993 KDX 250 Questions...

Are you sure that cylinder is ok to run? I see some shiny spots and that tends to indicate the plating is gone in that spot and what you are seeing is the aluminum base metal. Also, considering how thin plating actually is, any ridge at the top would indicate it is very worn.

Youtube Channel: WildAzzRacing

AZ State Parks & Trails OHV Ambassador - Trail Riders of Southern AZ

Current KDX: '98 KDX220

Old KDX: '90 KDX200 -White/Blue

'11 GasGas EC250R

AZ State Parks & Trails OHV Ambassador - Trail Riders of Southern AZ

Current KDX: '98 KDX220

Old KDX: '90 KDX200 -White/Blue

'11 GasGas EC250R

- KDXGarage

- KDXRider.net

- Posts: 14652

- Joined: 06:45 am Nov 01 2004

- Country: United States of America

- Location: AL, USA

- Has thanked: 4 times

- Been thanked: 8 times

- Contact:

Re: 1993 KDX 250 Questions...

You can lead a horse to water.

Thank you for participating on kdxrider.net.

To post pictures from a device: viewtopic.php?f=88&t=24128

To post pictures from a device: viewtopic.php?f=88&t=24128

-

Rangerman

- Member

- Posts: 23

- Joined: 08:59 pm Feb 25 2018

- Country: United States

Re: 1993 KDX 250 Questions...

Jason wrote:You can lead a horse to water.

This comment was not necessary at all and a bit to snarky for me given that all I have intended to do is post this experience to hopefully be of benefit to others who may have similar issues.

I have not even attempted to clean up the cylinder yet in any way and you have already determined it needs to be re-plated?

I have also cross posted this experience in a more limited fashion on another trusted forum and received quite different responses from two specific sources that I personally confide in that have a different opinion based on their experience and given this KDX's intended use.

I am not an expert in these matters nor have I suggested otherwise I just thought that since this was a KDX specific forum that I would give a detailed account from start to finish of issues that I am encountering that others may be able to glean from now or in the future.

Perhaps you might re-examine the way that you respond to others who contribute to this forum in the future as you might do more harm than good by turning potential contributors away with inappropriate responses to their questions and/or decisions.

Rangerman

CLW87

"We go way back, you and me"

"We go way back, you and me"